Have you ever thought about buying a laser? Laser engraving/cutting technology is becoming more accessible to craftspeople and fabricators all around the world, allowing a new generation of makers to have plenty of options for realizing their DIY ideas and manufacturing projects. Although laser machines can now be rented and operated by almost anybody, the transparency of how these machines actually function and what steps are required to operate one still need improvement.

Creating your first laser engraving work could be an intimidating process, but it doesn’t mean it have to be. No matter you’re new to working with complex technology or not, laser engraving or cutting is actually a relatively straight-forward process that enables the people without much expertise to create something interesting at a relatively lower price.

Therefore, this article is aim to give you a brief introduction about laser engraver/cutter, the reasons and tips you need to think before purchasing. Besides, to be more specific and comprehensive, I will take TwoTrees TS3 laser cutter as example.

What is laser?

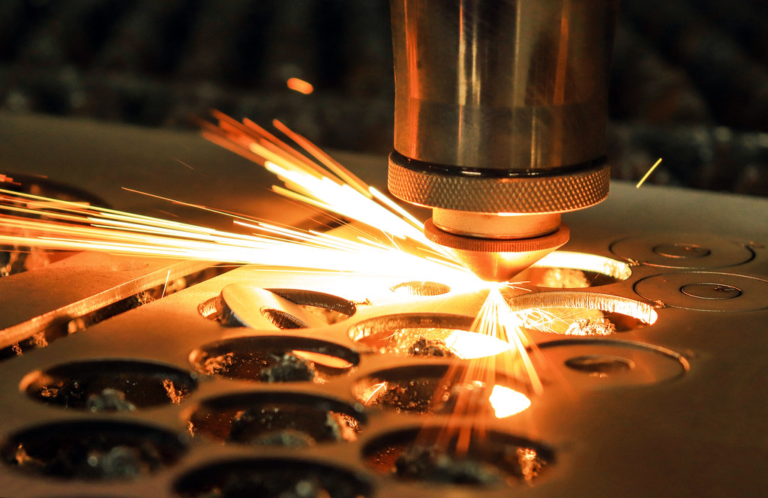

As the name suggests, laser cutters create patterns and designs by cutting into materials. A powerful laser beam is the source that melts, burns, or vaporizes the material.

In essence, laser engraving or cutting is a manufacturing process that uses a laser beam with high directivity, monochromaticity and coherence to cut and etch materials into custom patterns, and shapes as specified by designers. This non-contact, thermal-based manufacturing process is ideal for lots of materials, containing wood, glass, paper, metal, and acrylic. It’s also able to produce intricate parts without custom-designed tools.

It is different types of lasers used in the machines that divide laser cutter into several types. And what kind of laser are used also determines the thickness of material that the laser may be able to cut. Generally, a high-powered laser will be ideal for professional applications while it also expensive. On the other hand, a low-power laser is effective for thinner materials like plastics, card stock, paper, and wood, and satisfying most of the daily application need. And in this article, I will focus more on the non-industrial-level laser cutters.

The two main types of customer-level lasers are diode laser and CO2 laser. TS3 is a typical diode laser but with a closed sealing structure which is thought to belong to the feature of CO2 laser. The merits and demerits of these two kinds of lasers are discussed in my last article, if you are interested in it, you can click here to read.

Something You Need to Consider Before You Buy a Laser

- Do they have tech support?

To be honest, the only one thing that you can rely upon is that nothing lasts forever, that is, all machines will fail at some point for some reasons.

It means you still could encounter some problems even though you brought an expensive and seemingly perfect machine. It’s rather vital to make sure that you will be treated well and your problems with the machine will get solved as soon as possible. Therefore, you need to pay attention to whether the tech support is offered and from what sources like official community and group.

So I believe that if you take a TS3 home, with 30+ R&D staff from professional fields, TwoTrees can offer you tailored and technical support to work your problems out.

- Are there tutorials on how to use and/or fix the machine?

It does matter that there are tutorials about the machine provided by the company you buy from, including introduction and assembly manual in any accessible formats, especially for beginners in this field.

As a reliable company, TwoTrees has prepared a detailed introduction and several tutorial videos, every operation of the TS3 included, and keep uploading latest videos and articles all the time.

- Is a laser engraver difficult to learn how to use?

If you are concerned about learning how to use a laser engraver, that shouldn’t be the reason to hold you back from the decision of buying. The starting may be not joyful, but once you have your own engraving or cutting work done, you will have endless fun from then on. Normally, once the system and the laser engraver has been set up it is simple to understand how to use.

Here, the out-of-box machine, that is, no need of assembly, is most desirable option for you. It frees your troubles on the complex assembly and saves your time. More importantly, TS3 can be operated with the specific App which is extremely simple and friendly to use. And the touch screen on the machine also very clear for every order with detailed manuals.

- What size of a laser engraver do I need?

The machines bed size will determine how big a piece of material you can fit in the machine to cut or engrave. A bigger bed will allow you to cut or engrave larger pieces and even if you doing something small. Additionally, it also allows to cut out multiple pieces at once rather than one at a time, like TS3, it has an engraving size with 300mm*200mm. If you are working on smaller projects, TS3 desktop laser cutter is an excellent option as well.

- What power of a laser engraver do I need?

The strength of the laser is measured in Watts. The more watts the more powerful the laser is. The strength of the laser is most important for cutting. And the thickness of material that a laser can cut is determined by the focal point of the lens and the power of the laser. A more powerful laser will allow you to cut faster and more reliably.

Like TS3, it has 10 watts laser head, so it can cut 8mm plywood at one time and engrave much faster to save your waiting time.

- Where should I place my laser engraver?

Before you purchase your laser engraver/cutter, it is a good idea to think about where you will place it.

You need to make sure that you have enough space in your workshop or office for your laser engraver. And you also need to ensure that it is properly ventilated. This guarantees that air can circulate through the laser’s fans and keep the machine cool throughout the engraving/cutting process. What’s more, you are supposed to be able to plug it into an outlet that is able to provide the needed amount of power.

Thanks to the closed sealing structure, TwoTrees TS3 is thought to be a domestic laser cutter, that is, it can be placed at your home apart you’re your workshop or office. Its smoke filter helps efficiently purify the particles produced during engraving or cutting. Additionally, it also has several safety design which is mentioned in this article: link

Why I should buy a TS3?

You are allowed to engrave almost anything you can imagine on flat or cylindrical surfaces. It is a machine combining both safety and functionality, making it a must-have addition to any personal or professional workshop or craft space.

Where most lasers lack fourth-axis (for cylindrical engraving) compatibility or require a purchased attachment, TS3 has a built-in 4th axis ready to use out of the box. Its unit-body design also makes it less susceptible to component damage.

I would suggest you getting the TS3 laser to start with because it’s simple and friendly to learn and operate for most people.