As laser cutting and engraving technology keeps developing, the technology has been widely used for industrial production, commercial service providing and DIY projects. Thus which laser cutter & engraver to buy has become one most frequently asked questions for beginners. Before we find an ideal cutting & engraving machine, it’s important to have some basic knowledge of different laser cutter & engraver types in the market.

Laser Cutter & Engraver Types Explanation & Comparison

Fiber laser, CO2 laser and diode laser are three major players in the laser cutter & engraver market. Among them, the fiber laser cutting & engraving machine is with highest power & precision and costs (a fiber laser machine will cost at least $40,000) which is mainly used for industrial production. The CO2 laser is somewhere between fiber laser and diode laser used for both industrial production or consumer market. Diode laser cutting is the most common consumer solution with many outstanding features. Keep reading to find more details for each technology.

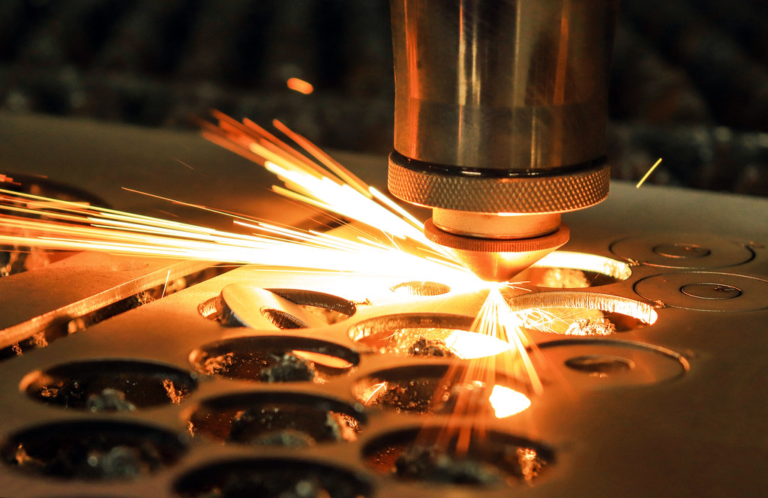

Fiber Laser Cutter & Engraver

Fiber laser cutting & engraving is done with fiberglass. The lasers originate from a “seed laser” before being amplified via special fibers.

Pros

- Highest Power — Fiber laser delivers the highest-powered laser beam among these three technologies. The exclusive style of a fiber laser light will allow it to generate a laser beam of higher quality with an affordable diode. Quality, in this term, depends on power and precision. When the laser is extremely-focused, it is powerful enough to easily cut through thick metals. With regards to strength, a fiber laser light can be 100 times more powerful than a CO2 laser machine.

- High Precision — The mechanism of internal reflections within the core of the fiber also allows for a fiber laser beam to be extremely small. Aside from the power magnification of such a design, it also means that fiber lasers are suitable for highly precise cutting and marking needs.

- High efficiency — A fiber laser machine is with 70%-80% energy efficiency which means most of the input power could be effectively used for cutting or engraving. In long term, it could save lots of power and money to operate a fiber laser machine.

- Resistant to noise and vibrations — The optical gain of a fiber laser is dependent on a medium that is inherently flexible. It does not rely on sensitive optics – instead, all its reflective components are housed inside the fiber. This makes a fiber laser much less sensitive to movement, vibration, or low-amplitude noise. This is quite advantageous in the heavy environments found in most manufacturing industries.

- Minimal maintenance costs — As fiber laser machine use affordable diode instead of highly sensitive optics thus very low maintenance are required and even if maintenance is needed, the costs would be only about half of other lasers.

Cons

Hight Initial Costs — Though using a fiber laser machine could save more power and maintenance costs in long term, the machine costs lots of money. A single machine with basic performance would cost at least $40,000 and a high-end machine could reach up to million dollars. That’s the main reason why you can hardly see any fiber laser machines in small factories.

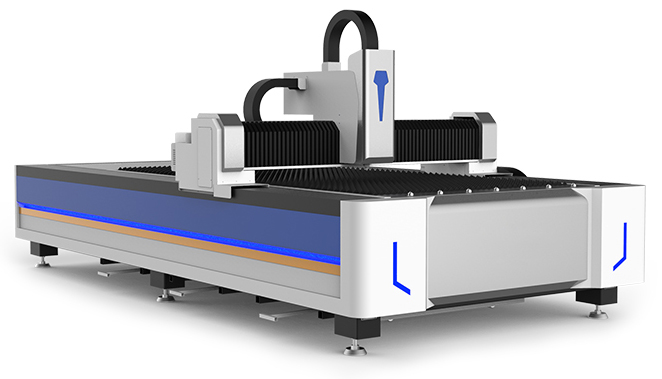

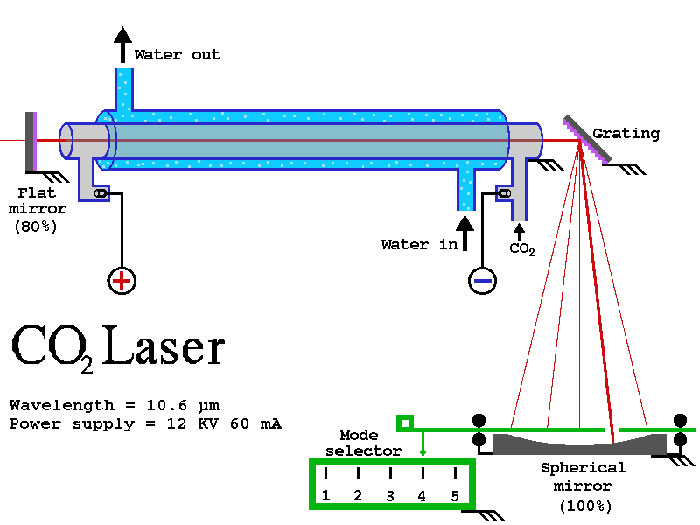

CO2 Laser Cutter & Engraver

In CO2 laser machine, cutting and engraving is done by using electrically-stimulated CO2 and other gases like nitrogen and helium. It emits a 10.6-mm wavelength, and a CO2 laser has enough energy to pierce through a thicker material compared to a fiber laser with the same power.

Pros

- More powerful — Compared with a diode laser, the CO2 laser is with a higher power. The output of CO2 lasers ranges from 25 W to a maximum of up to 400 W which allows CO2 lasers to cut through wood, acrylics, glass, and certain metals at higher speeds.

Cons

- Bulky Size — Due to the mechanism, the CO2 laser machine is usually bulky in size. It uses a long glass tube for optical gain, a cooling mechanism and an external housing case. All these make machine size huge thus it requires a large workspace to set up the machine before operation. What’s more, if you need a CO2 laser machine with higher power and precision, a larger gas tube and corresponding larger cooling mechanism would be needed.

- Vulnerable Construction — Aside from its bulky design, the CO2 laser is also very fragile since the CO2 laser tube is extremely fragile and easy to be broken apart. Moving a CO2 laser machine frequently is not considered good practice because of these characteristics.

- High Costs — As engineering requires higher precision for CO2 laser, it’s normally more expensive than diode lasers. This is certainly one main reason why CO2 lasers are not normally useful for hobbyist software or small bulk production businesses. What’s more, the costs to maintain or replace tube is also really high.

- Safety concerns — As a laser beam from a CO2 laser machine is invisible to naked eyes, special attention should be paid for safety concerns.

- Mirrors — CO2 laser is with intricately positioned mirrors. These mirrors could not be removed from alignment to avoid the laser stops working as intended. If you check reviews for CO2 laser machines on the website and might find complaints about spending months to get the right beam focus but get nothing work out.

- Material Limitation — Though the CO2 laser engraving machine is with a higher power, it is still somewhat limited on metal engraving and requires masking materials for too reflective metal surface.

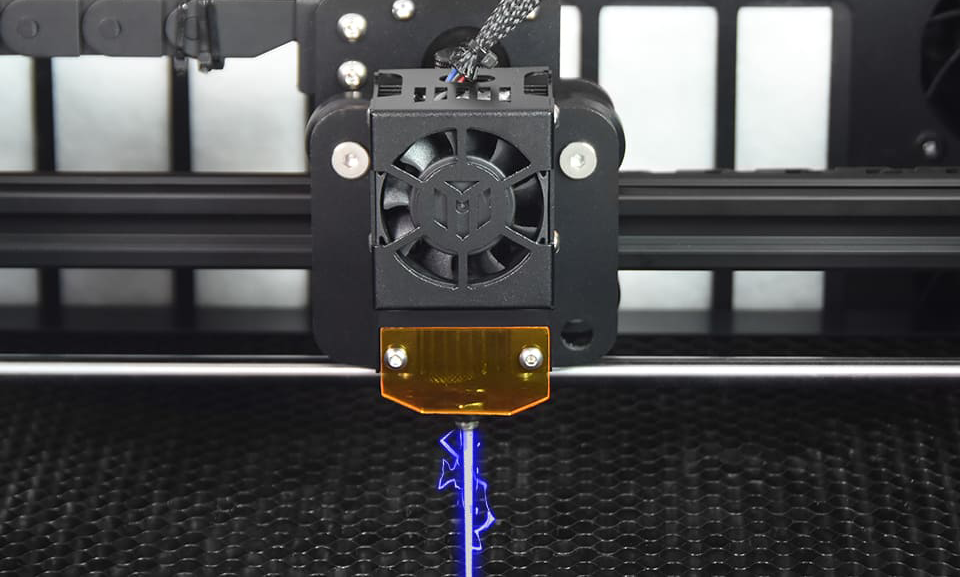

Diode Laser Cutter & Engraver

Diode lasers are the most common consumer machine on the market. Electrical current is supplied through the diode, inducing the flow of electrons through the p-n junction. These electrons combine with holes on the other side of the junctions, in turn releasing excess energy in the form of photons.

The gap between the two semiconductors acts as the “mirror” that magnifies the intensity of the photons. The photons bounce back and forth across this gap and also collide with other incoming electronics. This “resonance” helps produce even more photons. It takes several hundred collisions to attain the desired optical gain in a diode laser.

In more complex applications, several semiconductor diodes can be stacked together. The multiple beams from these diodes can be focused into a single beam, making the output considerably more powerful. This also makes it possible to create multiple lasers with different wavelength values.

Pros

- Diode laser cutters & engravers are usually designed as small and lightweight units. The compact portable design enables it to be transported easily and with fewer costs.

- A diode laser unit is usually over 8,000hours lifespan which means you might not need to replace it forever.

- A laser cutting or engraving machine is usually with controller allowing users to choose different power levels to achieve different effects.

- A diode laser cutter or engraver is much less expensive compared with a CO2 laser machine. A pretty good Co2 machine would start from 2-3K USD. The use of a cheaper one might cause more headaches than joy. This has made diode lasers quite popular in the hobbyist community and for those who want to start small enterprises.

- The diode laser machine is also easy to use since its semiconductors do not need to be aligned perfectly to work. Compared with a diode laser, CO2 laser machines get many complaints about having difficulty getting perfect laser focus for cutting and engraving.

Cons

- Most diode laser machine is not as powerful as CO2 laser.

- Limited materials -Diode lasers do not have enough power to engrave metal or glass unless some coating has been applied to them. Diode lasers also struggle with any surface that is glossy, transparent, translucent, or painted completely white.

CO2 vs Diode Laser Cutter: Which One Should I Buy?

The fight between CO2 and diode laser cutter has been there for quite a long time. However, all doubts would be removed if performed basic research. Diode laser cutters and engravers are featured for their competitive price, compact size, ease to use and more durable application. These also make diode laser cutting & engraving machines king of the consumer market as it is more practical for multiple casual uses. If you decide to start a laser engraving business, the diode laser is also a great option (check our post “Can you make money with TS3 laser cutter & engraver?” to find out how to start a laser cutting & engraving business).

The CO2 laser is known for its higher power, precisions but costs as well. By costs, it does not refer to its initial costs only. The CO2 tube is fragile and low-quality tubes have a high diffusion rate what makes them useless within 6-12 months and costs for new replacement is terribly high. Costs for owning and operating a CO2 laser machine can get very expensive as it is finicky, fragile, takes up a larger workspace and requires a higher level of skill to operate. It also needs more stringent safety measures to use such a machine as its laser radiation is invisible to naked eyes.

Which laser cutter & engraver to buy — Factors Need Consideration

Is the laser cutter & engraver powerful enough for you?

The first thing to look into before buying a laser cutter or laser engraver would be if the machine is powerful enough to cut thickness that delivers your design. For example, if you are planning for wood cutting projects, a lower power DIY laser engraver might fail to cut through the wood. Thus it’s important to confirm the laser power especially when some sellers might claim their machine with 40W or 20W power (this is actually the output power but not the working laser power) but actually only has 5W laser power (this misleading information is quite common in reselling websites).

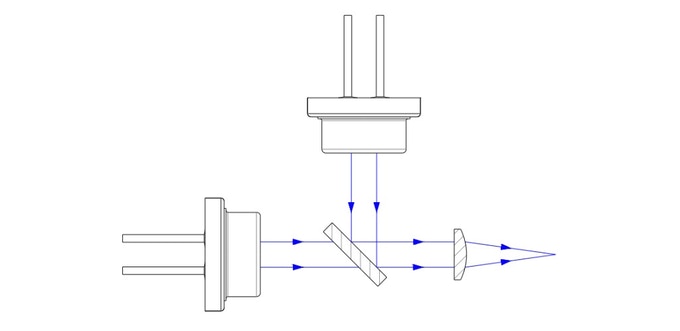

To get a powerful laser with strong penetration force, TS3 laser cutter & engraver uses its unique LD+FAC+C technology to get a super-strong laser beam. Two independent semiconductor diodes are working together. The multiple beams from these two diodes can be focused into a single beam, making the output more powerful ( tested laser power is 10W). Compared with most desktop laser cutters & engravers that cut 3mm Polywood, TS3 could easily cut through 8mm Polywood with a single cut.

What materials does the machine work on?

Except for laser power, materials workable for laser cutter & engraver are on top of the list for factors to concern. One advantage of laser cutting & engraving machines over CNC machines is the wide range of workable materials in the market. Different machines might suit different materials and make sure to check with the supplier about this before placing orders.

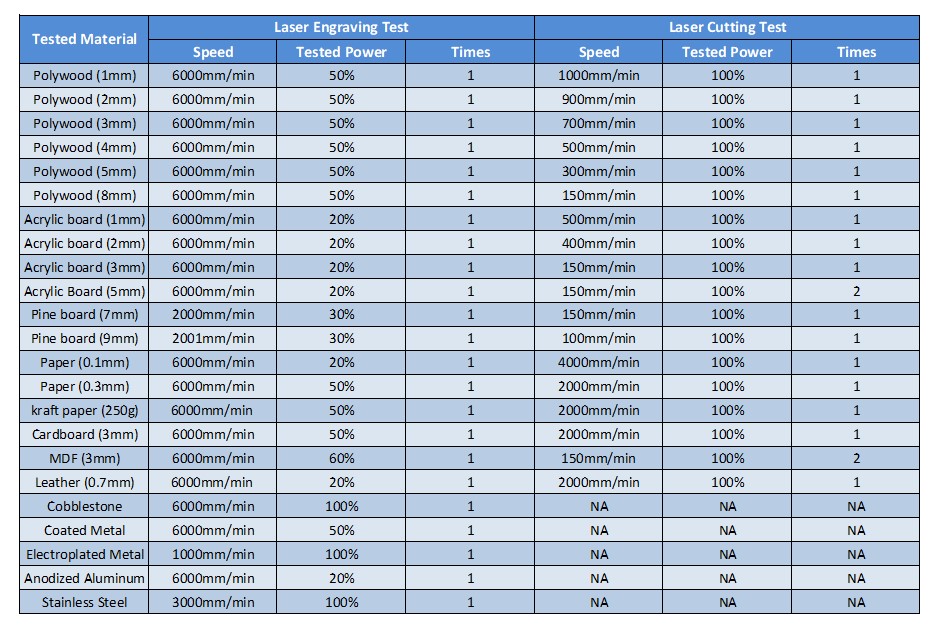

Here are some tested materials that have been proved workable for TS3:

Is it legal to use the laser cutter & engraver?

Before making your purchasing decision, it’s important to make sure if the laser cutter & engraver are against local law or regulations. One main reason why our TS3 machine is with metal enclosure is that some government requires closure for laser cutting machine for safety concerns.

Is the laser cutting & engraving machine safe to use?

As laser cutter & engraver would generate massive heat during the cutting and engraving process, safety should always be one major concern. There are a few factors you might check with the supplier to confirm if it’s safe enough to have the machine in your house.

- Flame Detector- To ensure users’ safety, like TS3 laser cutter & engravers, some laser cutting machines would also be built with integrated smart flame detectors. The flame detectors could easily find any flame and send information to the motherboard for corresponding actions before flame developed into fire accidents.

- Fire Alarming System – Once any flame is found, the warming signal LED would start flashing and TS3 would send loudly fire alarming which could be heard easily.

- Auto-shutdown System – TS3 is also configured to shut down once any flame is detected to prevent more heat making the situation worse.

The 2nd safety concern would be laser radiation. It’s common sense you should never look directly at the laser beam when it’s running, especially if there is no protection between the laser and your eye. Staring directly at the laser cutter can damage your eye. Instead of using glass goggles, TS3 is built with laser safe windows which allows enjoying the laser cutting & engraving process with friends and family members.

The 3rd safety concern is inevitable for all laser cutting & engraving machines but could be avoided by not cutting specific materials as they might release toxic fumes or cause fires. To address this issue, TS3 is built with an integrated internal circulation system to force fumes into our smoke purifier with active carbon pad.

Though this improves the situation it’s recommended to avoid some materials. Here is a list of materials that we should avoid cutting:

| Material | Notes |

|---|---|

| Coniferous woods | Uneven grain structure with soft and hard areas. Hard to find a good power setting. |

| Oily/resinous woods | May catch fire. |

| ABS | Emits dangerous cyanide gas and melts. It’s safe to 3D print but not to laser cut. |

| PVC | Emits pure chlorine gas which will ruin optics and corrode the metal of the machine. |

| Thick Polycarbonate | Cuts poorly and could catch fire. |

| HDPE | Melts and catches fire. |

| Polystyrene foam | Melts and very likely to cause fire |

| PolyPropylene foam | Melts and catch fire |

| Fiberglass | Emits fumes. Epoxy releases toxic fumes. |

| Coated carbon fiber | Cannot cut when coated. |

| Glass | Generally doesn’t cut well without special laser cutters. |

| Stone | Cannot be cut with lasers. |

Is cutting & engraving space enough for your projects?

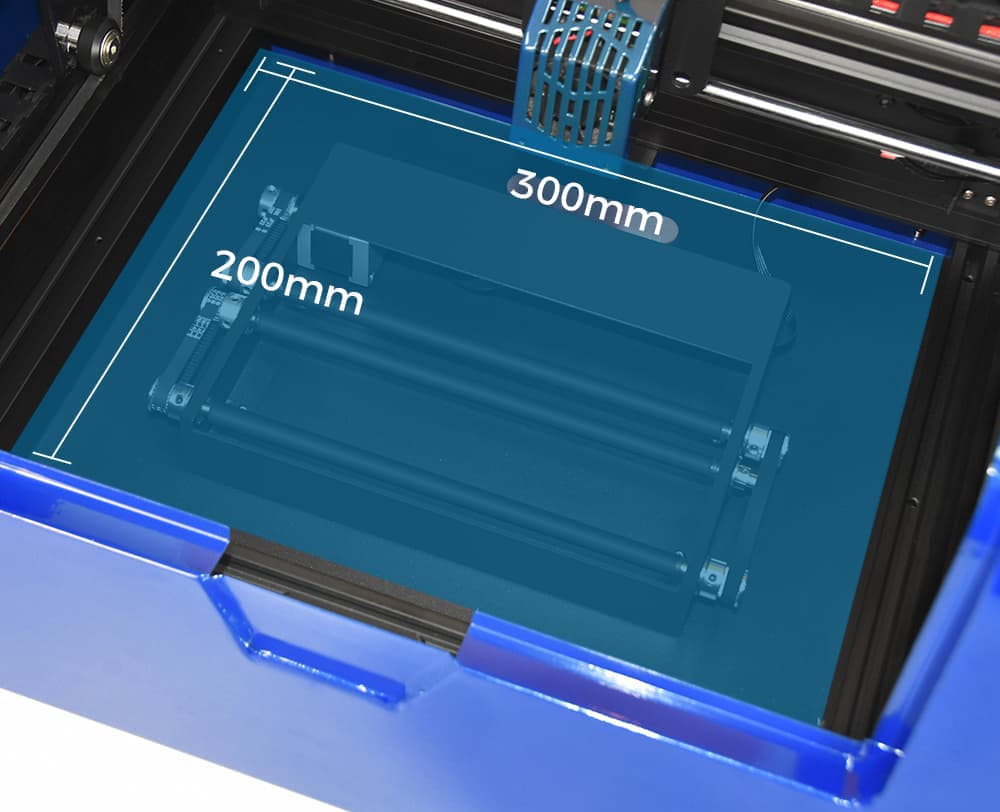

The size of your design is limited by the dimensions of the cutting platform. Operation space is also an important factor to consider especially when your project involves big-size objects. If your cutting objects are large in size, it’s quite reasonable to consider using a cutting machine with an open structure or bulky machines. As one desktop laser cutter & engraver, TS3 provides 300x200X102mm operation space as one machine with the largest cutting and engraving area.

What’s the precision of laser cutting & engraving machines?

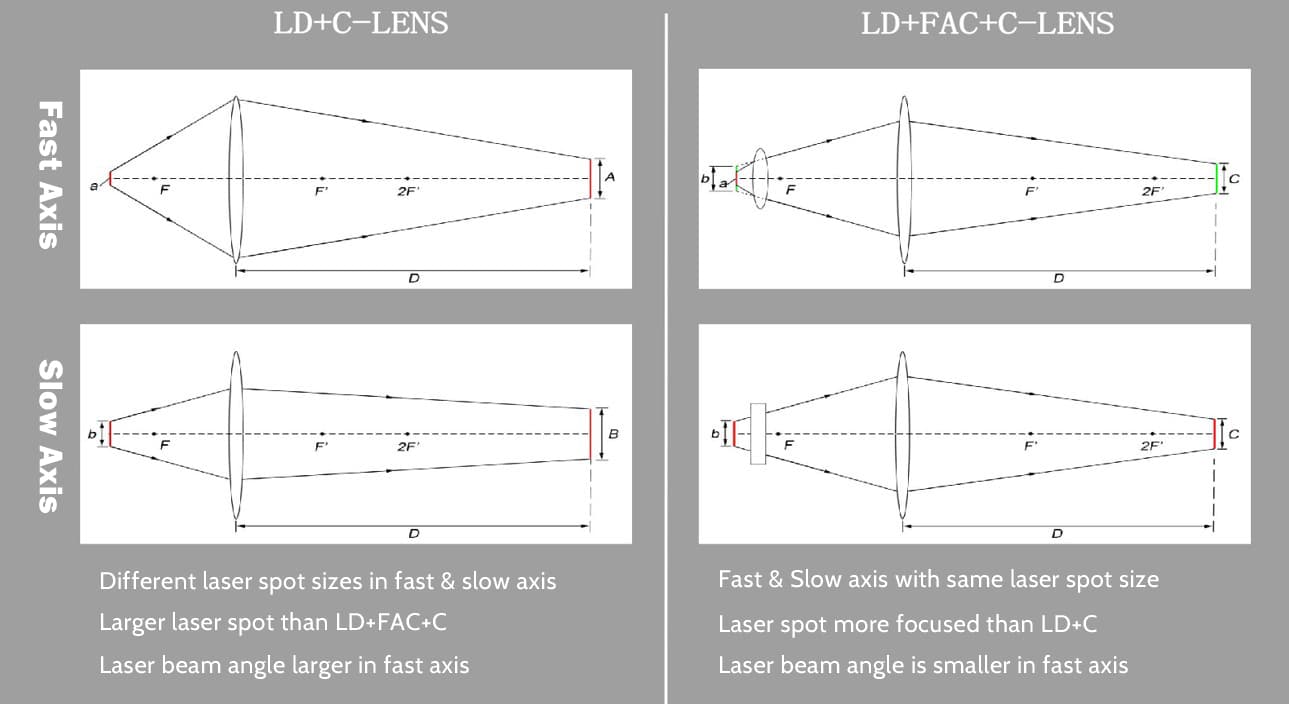

Would the cutting & engraving machine offer clear and smooth lines? Precision is extremely important if you are building a brand for laser cutting or engraving service. Blur lines might lead to business failure or losing money if the precision is lower than your design. To get higher precision, TS3 uses LD+FAC+C-Lens technology to get steeper laser beams and more focused laser spots of 0.08mm diameter.

Compared with the general LD+C-Lens technology used by most other laser cutters & engravers, this unique technology has a few outstanding advantages:

Others

Except for the above factors, there are many other factors that might need your attention.

- Rotatory roller: if your design is for a curved/cylindrical surface like a wine bottle, a rotatory attachment would be necessary.

- Cutting/engraving speed: the higher the speed, the less time needed for each project, the lower precision would be. It’s all about balance and could be controlled via software settings in most cases.

- Costs: Both costs for initial costs or maintenance costs should be taken into consideration.