【Compressed Laser】TT-5.5S is a powerful laser engraving machine with advanced LD+FAC technology for a compressed laser beam to achieve fast engraving speed & high precision.

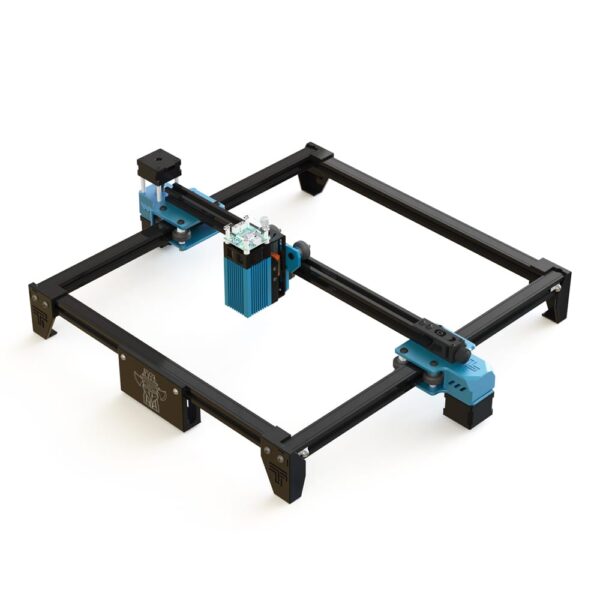

【2-in-1 Machine】It is one desktop home laser engraver & laser cutter all in one machine.

【Mini & Pro Kit】It’s compact size and much higher performance to meet demands for professional projects.

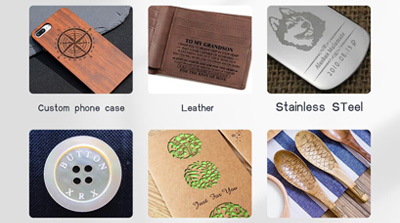

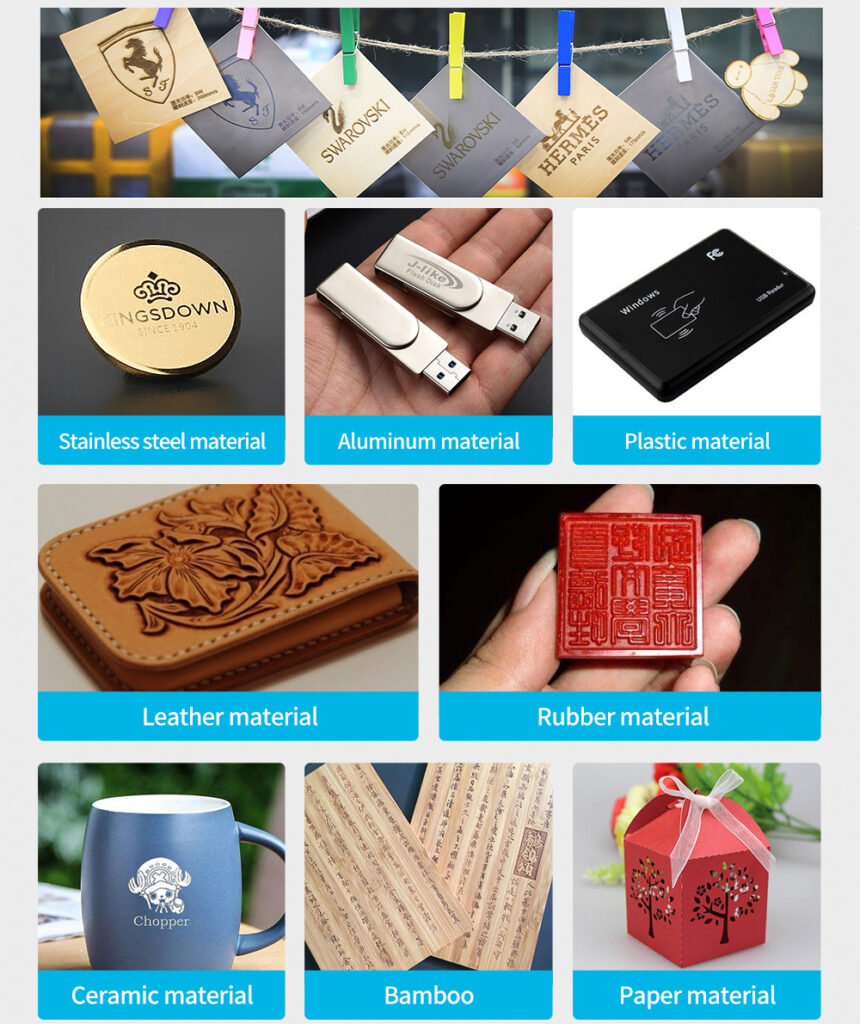

【Wide Compatibility】Laser engraving & cutting machine for stainless steel, wood leather, alumina, steel, etc.

3D laser printer is a laser engraving machine that uses a laser instead of ink to achieve 3D object creation. The more general and popular phrase to the general public is laser engravers and cutters. With powerful and compressed laser spots, 3D laser printers are enabled to cut through or leave trails on multiple materials for amazing design results.

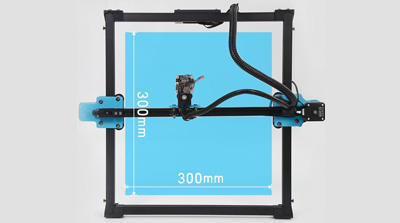

TT-5.5S is a powerful desktop 3D laser printer laser engraving machine using LD+FAC+C-lens technology with 0.08mm compressed laser spot for stronger engraving and cutting capabilities. Its 300*300mm cutting space allows users to process various materials of different sizes and realize their full potential of creation.

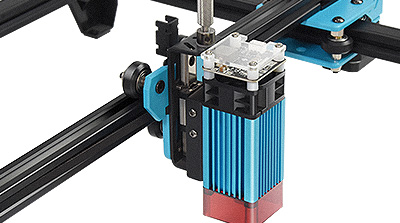

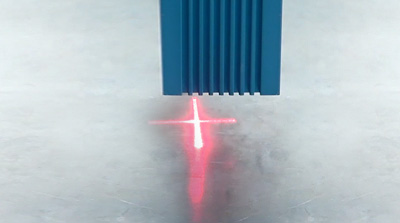

Latest LD + FAC compressed Spot technology to obtain more powerful 0.08mm laser spot with more concentrated and higher precision to reduces the engraving time.

With a fixed-focus, the Z-axis lifting table enables lower or raise the height of the laser head (0-40mm) to achieve the best engraving/cutting effect for different materials and heights.

Anti-slip foot pad design, easy to install and makes the machine more stable.

300*300mm large carving area, provide enough space for most DIY projects. Without limit of carving height, so you can carve and cut multiple materials as you like.

The belt tensioner makes it easier and more convenient to adjust tightness of X-axis to avoid the engraving staggered layer caused by the loose belt and achieve higher accutacy.

The red auxilliary light helps users set the right positioning easily without extra settings.

No need to adjust the focal length before engraving. And the new laser offers both the possibility of precision engraving and high-energy cutting functions.

Suitable forvarious materials such as leather, wood, MDF, acrylic, cardboard, bamboo, anodized aluminum, stainless steel, plastic, ceramics, paper, rubber, sponge paper, etc.

Compatible with LaserGRBL, LightBurn or BenBox for Windows, Mac, Linux system. Supports image file formats like NC, DXF, BMP, JPG, PNG, etc.

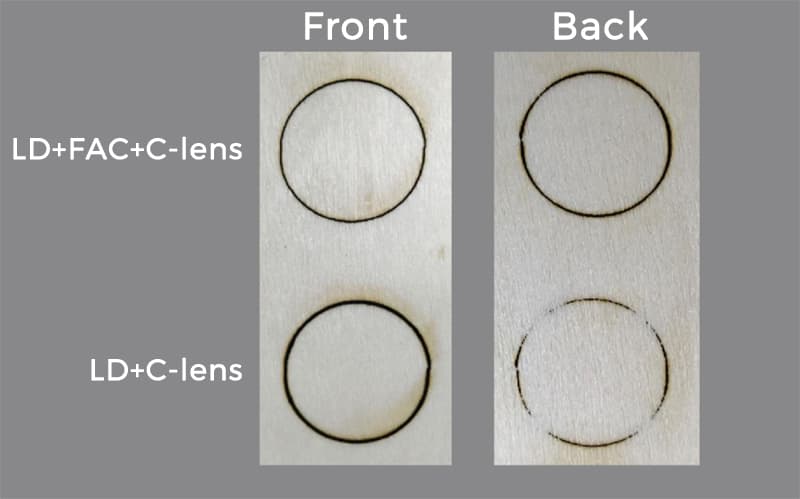

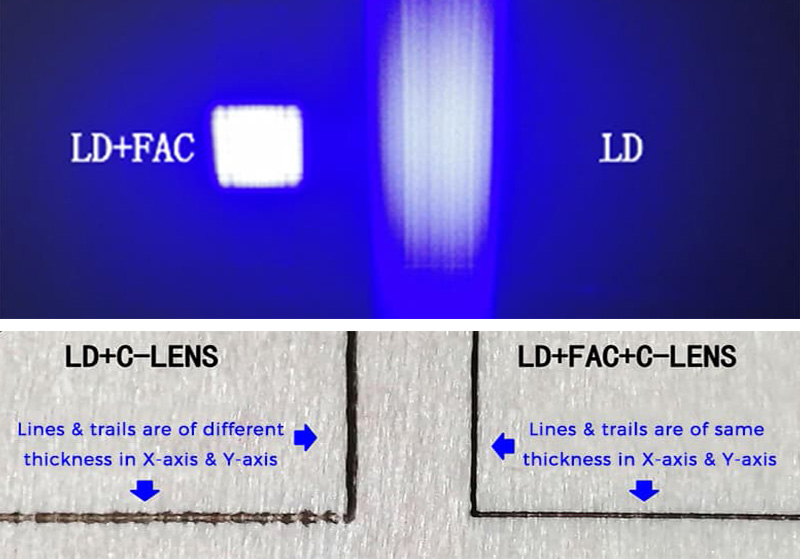

To get a better idea of the difference, we have tested to cut a 4mm wood with single LD of both LD+C-lens and LD+FAC+C-lens technology. Here is a cutting performance comparison image of the different technology. You might also check the left testing comparing images to cut 4mm wood with single LD.

Compared with LD+C-lens technology, the LD+FAC6-+C-lens cuts a deeper depth with clearer & thinner lines and leaves fewer burning trails.

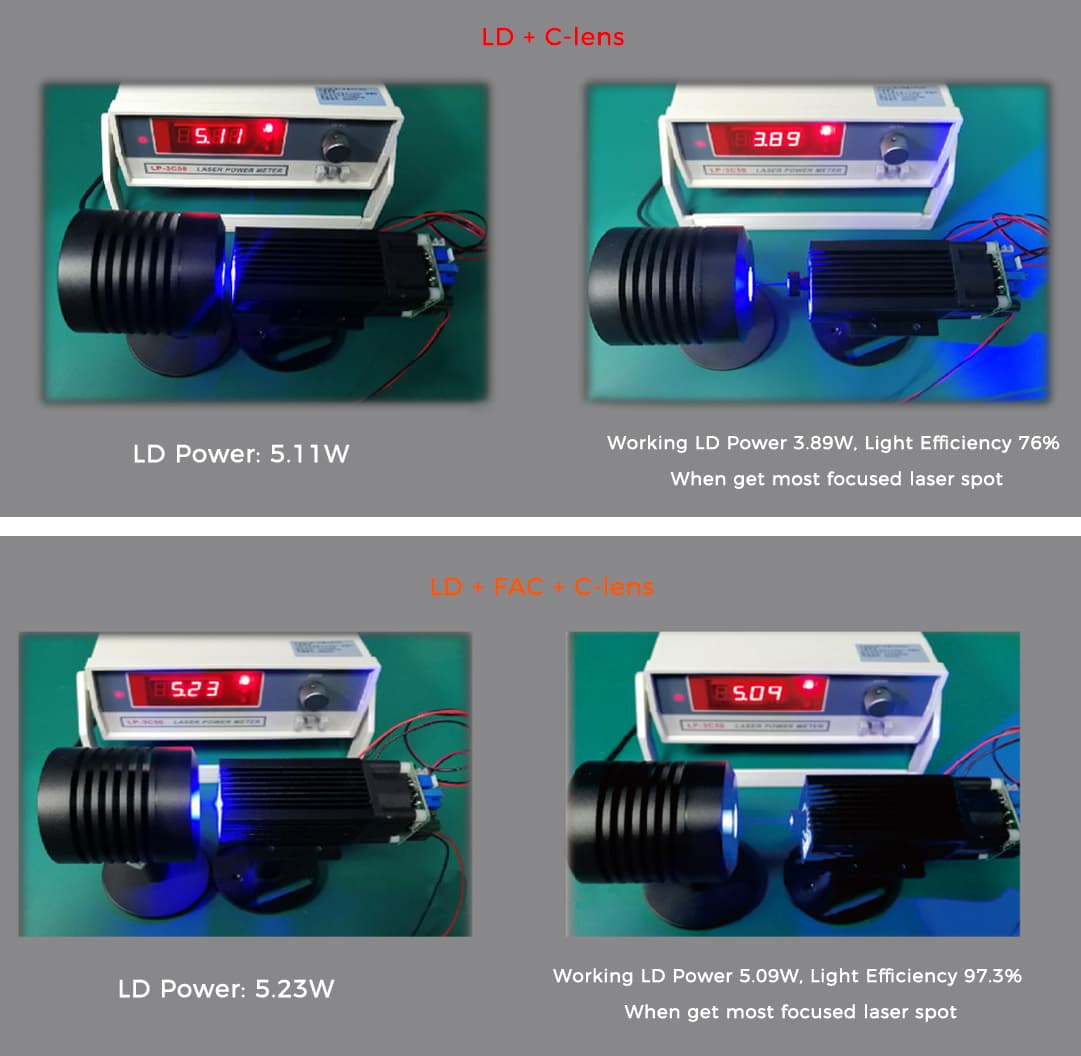

These two technologies also perform quite differently in terms of light preservation and transmission. To prove the difference, we run a test for both technologies. We tested the original LD power and the working power of the most focused laser spot. For LD+C-lens, only 76% of the 5.11W light from LD is efficiently converted into the focused laser spot with a working power of 3.89W.

However, 97.3% of the 5.23W laser light is converted into the 5.09W laser spot through LD+FAC+C-lens technology. It’s obvious that LD+FAC+C-lens has a higher working power and is more efficient in light transmission.

Because of the 0.08mm compressed laser spot which is much smaller than that from LD+C-lens technology, it provides clearer & thinner cutting lines & trails as the left image shows. What’s more, since the light from LD+FAC+C-lens is collimated, the device has the same laser spot size at both fast-axis and slow-axis directions.

The collimated light beam not only preserves more light sources for higher power but also presents well-balanced cutting & engraving lines from horizontal & vertical directions. This might be safely ignored when cutting circles but have a great impact beyond your imagination while cutting a rectangular design. If you have no idea, the left image would remove your confusion.

| Device & Material | TT-5.5S | Remark | |

|---|---|---|---|

Rotate the laser head column to adjust the height to focus the spot Distance from laser head to engraving surface:(24MM) | |||

| Specification | Testing Type | Rated Power: 5.5W Tested Power: 4.98W | |

| Plywood (1MM) | Engraving | 2000mm/min 30% | In actual operation, the hardness of the wood board being operated is different, and the cutting speed of different types of machines is set differently. |

| Cutting | 400~500mm/min 100% | ||

| Plywood (2MM) | Engraving | 2000mm/min 30% | |

| Cutting | 300~400mm/min 100% | ||

| Plywood (3MM) | Engraving | 2000mm/min 30% | |

| Cutting | 200~300mm/min 100% | ||

| Plywood (4MM) | Engraving | 2000mm/min 30% | |

| Cutting | 100~150mm/min 100% | ||

| Plywood (5MM) | Engraving | 2000mm/min 30% | |

| Cutting | 100mm/min 100% *2 | ||

| Plywood (8MM) | Engraving | 2000mm/min 30% | |

| Cutting | X | ||

| Acrylic Sheet (1MM) | Engraving | 6000mm/min 20% | The acrylic board used in the test is pure black. |

| Cutting | 100~200mm/min 100% | ||

| Acrylic Sheet (2MM) | Engraving | 6000mm/min 20% | |

| Cutting | 100~150mm/min 100% | ||

| Acrylic Sheet (3MM) | Engraving | 6000mm/min 20% | |

| Cutting | 150mm/min 100% *2 | / | |

| Pine Board 7.0mm | Engraving | 2000mm/min 40% | / |

| Cutting | 100mm/min 100% *2 | ||

| Pine Board 9.0mm | Engraving | 2000mm/min 40% | |

| Cutting | X | ||

| Color A4 paper 0.1mm | Laser engraving | 6000mm/min 45% | / |

| laser cutting | 4000mm/min 100% | ||

| Color A4 paper 0.3mm | Laser engraving | 4000mm/min 80% | |

| laser cutting | 1500-2000mm/min 100% | ||

| 250g/sq.m Kraft Paper | Engraving | 4000mm/min 80% | / |

| Cutting | 1500-2000mm/min 100% | ||

3mm Cardboard (Carton) | Engraving | 6000mm/min 80% | / |

| Cutting | 300-400mm/min 100% | ||

| Leather 0.7MM | Engraving | 6000mm/min 80% | / |

| Cutting | 700mm/min 100% | ||

| Non-woven Fabric (0.5mm, darker color) | Engraving | 6000mm/min 60% | Cause the material to burn through. |

| Cutting | 2000-3000mm/min 100% | ||

| Dust-free Cloth (white) | Engraving | X | will cause the material to melt. |

| Cutting | 50-100mm/min 100% | ||

| Gauze | Engraving | X | will make the material black. |

| Cutting | 300mm/min 100% | ||

| Plastic Board (In darker color) | Engraving | 6000mm/min 70% | Cause the material to melt and form a buildup. |

| Cutting | X | ||

| Acrylic 5mm | Engraving | 6000mm/min 20% | / |

| Cutting | X | ||

| Tinned Wire | Engraving | X | / |

| Cutting | X | ||

| Cobblestone | Engraving | 3000mm/min 100% | / |

| Cutting | X | ||

| Ceramics | Engraving | X | / |

| Cutting | X | ||

| Powder coated metal Spray paint (metal) | Engraving | 5000mm/min 50% | / |

| Cutting | X | ||

| Electroplated Metal | Engraving | 300mm/min 100% | / |

| Cutting | X | ||

| Anodized Aluminum | Engraving | 4000mm/min 60% | / |

| Cutting | X | ||

| Stainless Steel | Engraving | 1500mm/min 100% | / |

| Cutting | X | ||

| Density board 3mm | Engraving | 5000mm/min 40% | / |

| Cutting | X | ||

| Laminated cardboard 5mm | Engraving | 4000mm/min 80% | / |

| Cutting | X | ||

| Model number | TT-5.5s |

|---|---|

| Type | Laser Engraving |

| Material | Aluminum + Plastic |

| Control board | MKS LKS |

| Laser wavelength | 450nm |

| Laser power | 5500mW (LD+FAC) |

| Engraving Size | 300*300mm |

| Laser input | AC100-240V |

| Power supply | 12V 4A DC |

| Plug | USA / EU / UK / AU Plug (optional) |

| Accuracy | 0.08mm |

| Engraving speed | 8000mm/min |

| Carving method | Computer Online Operation |

| Interface | USB |

| File format | .nc / .dxf / .bmp / .jpg / .png etc. |

| Engraving mode | image / text / scanning / outlining / pixel engraving, etc. |

| Support software | Laser GRBL/LIGHTBURN |

| Support System | Windows/Mac |

| Continuous working time | ≤6Hrs |

| Machine Size | L570*W485*H170MM |

Something isn’t Clear?

Feel free to contact us to inquire how to become the dealer or distributor, and we will be more than happy to answer all of your questions within 24-48 hours.