Are you looking forward to DIY laser engraver kit plans or coming up with an idea to buy an affordable laser engraver? Laser engravers aren’t new technology, but much like 3D printers, prices have crashed to the point where they’re now affordable for DIY enthusiasts. Here are some information for you to know as a freshman in this field.

Laser engraver is a type of laser machine with CNC (Computer Numerical Control) system that adopts Fiber/UV/CO2 laser beam to cut & engrave 2D/3D letters, numbers, texts, patterns, photos, pictures, signs or logos on the surface of the materials.

Laser Engraving is a subtractive manufacturing method that uses a laser beam to change the surface of an object.

This process is mostly used to create images on the material. To do so, the laser creates high heat that will vaporize the matter, thus exposing cavities that will form the final image. It is using the laser for marking the surface of an item.

The different laser types use different components and generate a light beam at different wavelengths – these wavelengths are suited to different types of materials that they can engrave upon.

Diode laser engraver

Diode lasers are rapidly becoming the most common consumer-level units on the market, for plenty of reasons:

– They are small and lightweight

– Cost far less (the cost of our TT series and TS3 is from $129 to $799)

– Have a fairly long lifespan (estimated at 8,000 hours)

– Power can be adjusted by the controller while operating to achieve grayscale effect.

– Friendly and convenient operation for most beginners as entry level laser cutter.

That said, diode lasers do have limitations – primarily the maximum power output. Most diode lasers have a maximum continuous output of approximately 8 watts (our TS3 has 10W).

We typically recommend the diode laser units for the majority of our customers – they work great for wooden designs and can placed and operate at home.

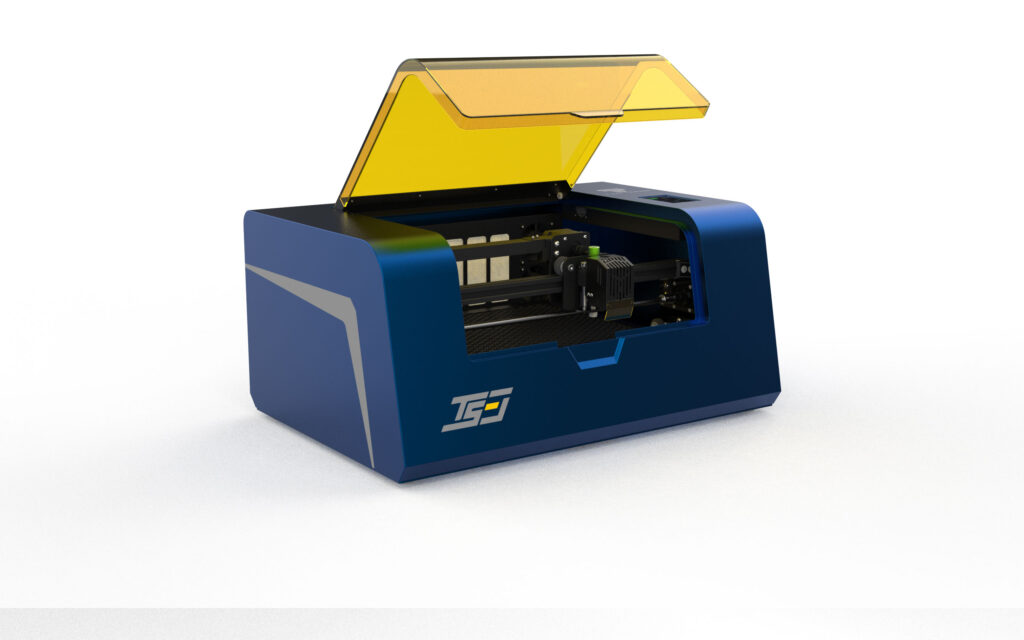

CO2 Laser engraver

CO2 lasers have one major advantage – power output. Our products are currently shipping with either a 40W or 50W laser tube – this is enough power to cut through thin woods and acrylics.

The biggest problem with a CO2 laser is simply its size – since the laser tube is fragile, and the laser beam is invisible to the naked eye; the machine must be fully enclosed for safety.

You can get a lot of different engraved materials, allowing to achieve interesting results. The engraving materials include synthetic wood, bamboo, leather, plastic, acrylic board, stainless steel, various paint and oxide layers, and can even cut 5mm thick plywood at one time with our TT-5.5S (8mm with TS3).

You can use laser engravers to produce wood cut puzzles, paper artwork, dog collar, keychain holder, leather wallets, etc.

Something isn’t Clear?

Feel free to contact us to inquire how to become the dealer or distributor, and we will be more than happy to answer all of your questions within 24-48 hours.