– Written by John Smith

Is a laser engraver worth it? If you are hesitating in purchasing a laser engraver, you are in the right place. The reasoning for such doubts might be that you either have no idea what you could achieve with a laser engraver or that the engraving machine is beyond your budget and perceived value.

Why You Need A Laser Engraver?

The laser engraver is an extremely helpful tool for developing your personal hobby and growing your business. The wide range of materials that it can engrave on and various creative ideas that could be brought into life can far beyond imagination. You might check our previous post to find some amazing ideas to engrave on objects and top creative design files to expand your engraving collection.

- Develop As A Personal Hobby: There are many hobbies in the world. Some are expensive ones like car racing and some are dangerous ones like bungee jumping. Laser engraving on the other hand is one of the most available hobbies that are much safer and could bring real value to your life.

- Grow Your Business & Brand Awareness: Laser engraving is also a promising business idea. The ever-growing demand for customization makes laser engraving a booming business. If you are considering a home business, why not try to start a celebration and event gift shop, engraved business cards company, engraving sign shop, etc.

- Create Personalized Gift: The most alluring feature of a laser engraver is its capacity for customization. This is an excellent tool to build personalized gifts for your friends and family.

- Make Life Easier & More Joyful: A laser engraver is much more than a toy. You can build lots of stuff that would make your life easier and more joyful. Some most popular things you can make with a laser engraver are laser wall decoration, customized coasters, engraved wood photos, jewelry boxes, etc.

Is a laser engraver worth it?

To decide if a laser engraver is worth it, you need to find answers to the following questions.

Q1: How often do you use a laser engraver?

If your work involves lots of laser engraving work, why not speed more to get a solid and durable laser machine. If the laser engraving is only a one-time job, finding a local service provider might be better (though the costs for a few services might be as high as buying a laser engraving machine by yourself.).

Q2: What power should I need for the laser engraver?

The materials and depth that could be engraved depend on the laser power of your machine. In most cases, a desktop 5W-10W laser engraving machine would work for most home projects. However, if you do require higher power for some sturdy materials and extra depth, you might pay more to get a more powerful machine.

Q3: What precision do I need?

Most consumer laser engravers in the market get 0.1m*0.1mm precision to get great details. If your project requires more delicate details, it’s also a reasonable decision to spend more to get a laser engraver with more accuracy.

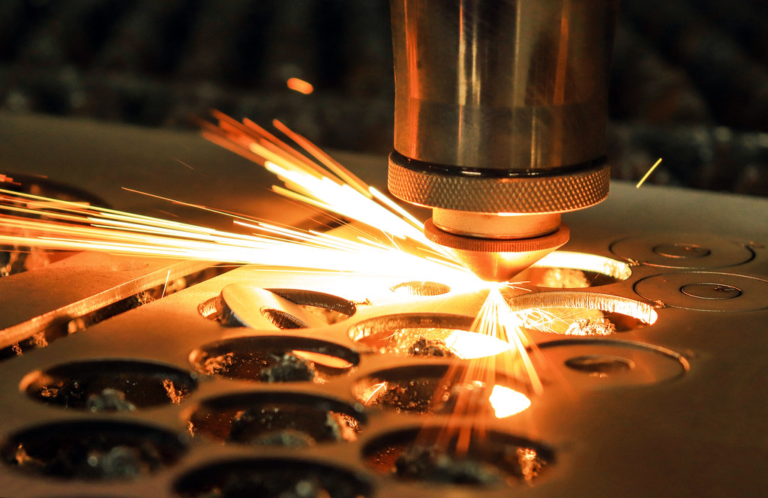

Q4: What Materials Will Be Engraved?

Different laser types work for different materials. If your materials cannot be engraved by a diode laser engraver, you might need to pay more to get a CO2 or fiber laser machine.

Q5: What Size of a Laser Engraver Do I Need? Where Should I Place My Laser Engraver?

If you work regularly on home projects and do not have extra space, a desktop laser engraver would be just fine for you.

How much does a laser engraver cost?

There are usually three laser types for laser engraving machines: diode, CO2, and fiber. A fiber laser machine will cost at least $40,000 and is usually used for industrial manufacturing. A CO2 laser with decent details would start at $2000. A diode is the most popular and most available laser type for desktop laser engravers and the price would start as low as $150. If you are a DIY enthusiast or small business owner, a diode laser engraver would be enough for all your engraving needs.

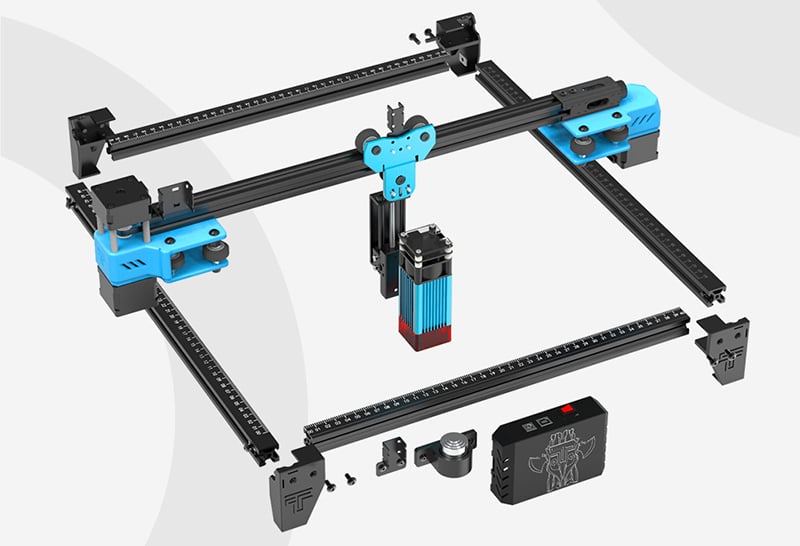

Best Value Diode Laser Engraver Recommendation

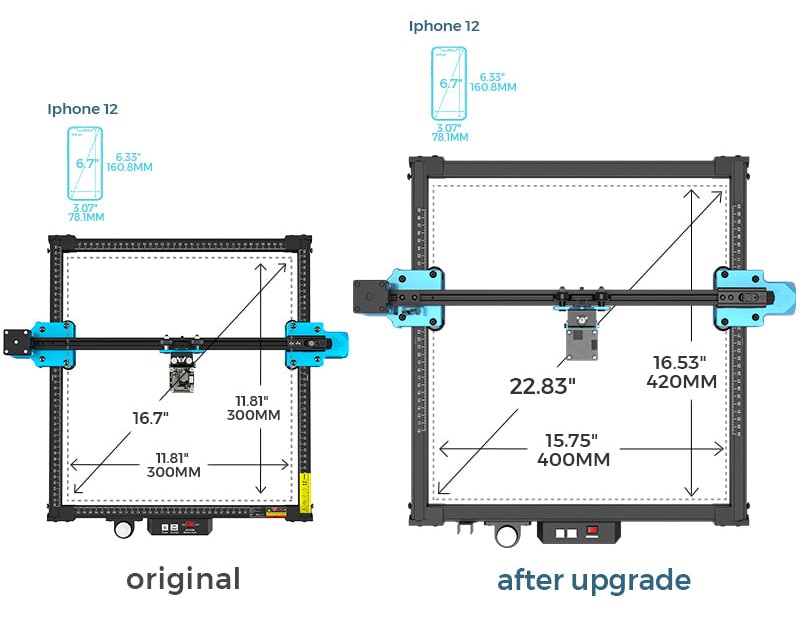

Among all diode laser engravers on the market, TTS-55 DIY Laser Cutter Machine is one with the best value. It’s fully built with metal frames and durable accessories. The advanced LD+FAC tech offers 0.08mm*0.08mm highly focused 10W laser for powerful cutting capacity, extra engraving depth, and delicate details. The optional extension kit allows users to expand the engraving area from 300mm*300mm to 420mm*400mm. What’s more, as a newly launched product, the new arrival deal price is only $299. If you are still searching for a high-performance machine with a competitive price, TTS-55 would be definitely a good option to try.

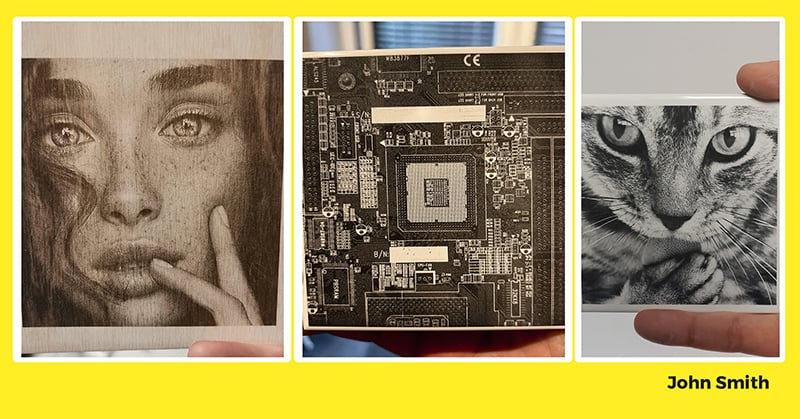

Hands-On Review From Two Trees Users

60% Pre-installed

You have simple, and then you have the TWO TREES TTS-55. It’s essentially a square frame of the bolted together extruded tube with the laser module mounted on runners aside. This enables the X and Y-axis movement of the tool head across the work area, all controlled by the computer-connected 32-bit mainboard and three stepper motors.

Wi-Fi & App connection

Like many production machines, TWO TREES requires a permanent direct connection to the computer, which must remain active during the engraving or cutting process, but the company made sure that you do not have to connect only with a cable. Thanks to the MKS DLC32 bit board, you can connect to the machine wirelessly (available WiFi connection app for android and ios). You no longer need a computer to be able to make beautiful projects.

Eyes Protection

There is a protection screen attached to magnets, so when the machine is running, you can easily be in the same room as the TTS-55. If you do not want to wear a protective screen REMEMBER you must wear protective glasses which are provided. ABOVE ALL, PROTECT YOUR EYES!

Engrave area

The big feature of the TTS-55 is the large engraving area of 300mm x 300mm which is impressive for a machine at this price. You can also pay extra to get the extension kit to expand the engraving area to 420*400mm.

The TTS-55 will keep you safe in emergency situations. If you see something disturbing happening, you can always press the ON / OFF switch. The machine will stop working immediately. Likewise, if you disconnect the USB for any reason, the laser will stop. Finally, if you manually turned on the laser, but for whatever reason, you do not move the tool head, the laser will turn off again after a few moments of inactivity.

Pixel Accuracy

Pixel accuracy is what defines the quality of laser cutters, and here the TTS-55 boasts 0.08 which is impressive.

By opening a box that is relatively small in itself, the TWO TREES TTS-55 is neatly arranged inside. If you have experience building such things, it will take 10 to 20 minutes, if not, then even the most inexperienced should have the construction completed within 30-40 minutes.

Lightburn

After completion, the device can be connected to the computer and the selected software can be loaded. Lightburn [30 days free trial] is by far the best software to use.

First Test

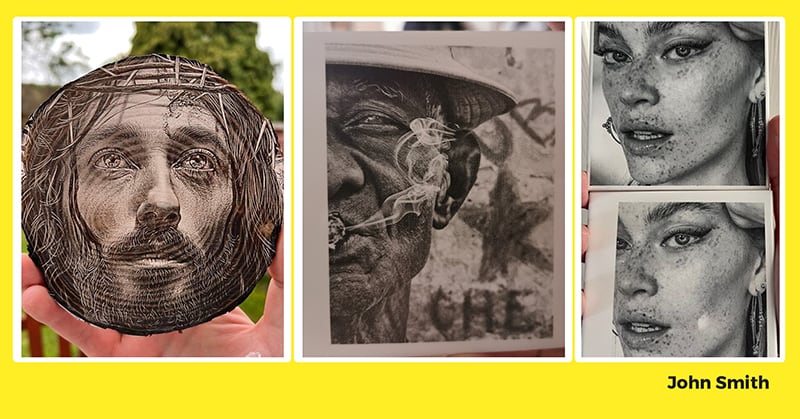

After checking the setup and running the first test, everything looked fine. The first laser test in etch mode fared well, and from a distance, the result was impressive considering the price.

If you’ve never used a laser before, if you’ve used laser cutting before, at school, at work, or otherwise, you’ve probably used a machine that is a little more manual. This is a tool that you need to experiment with to get the best out of it.

Fixing the machine corners downwards improved the strength and quality of carving and engraving at higher speeds. At speeds of 2400 or 3000 mm / min, there is no noticeable movement of the machine thanks to the use of the material under the legs of the machine that easily adheres to the surface and immobilizes the machine. It is important for most of the work that you do not create lines.

The transition to cut and laser power was immediately visible, and fine sharpness adjustments were made, along with adjustments to speed, laser power, and the number of passes. After a good hour or two of fine-tuning, I felt the results were as good as they intended.

I chose a 3mm plywood during the test and was able to get excellent results. The ceramic tile was also not a problem. Thanks to the TWO TREES machine, you can get a perfect image on a ceramic tile that cannot be removed because it is an eternally etched image.

At this price, the TWO TREES TTS-55 is unique, as long as you make sure you follow the instructions carefully when building it, then little can go wrong.

Easy to adjust the focus

If the focus is not in place, it is easy to adjust it with the manual Z-axis which, unlike the competition, is metal and accurate, and cheap and plastic in other manufacturers.

After testing, check for differences in cutting and carving techniques. You also need to familiarize yourself with the settings used between materials, after a little experimentation the TTS-55 then becomes itself.

However, for all the simplicity of this device’s potential, once configured it is easy to use and understandable. Lightburn type software and the TTS-55 provide customizations to make your life easier.

Expandable Support

Thanks to the use of profiles with dimensions of 20mm x 20mm, the versatility and the possibility of modification know no bounds.

TWO TREES is a truly universal modding device. My modifications consisted in changing the teeth from 20 to 16, which affects the quality of the engraved image even more precisely.

My next modification was moving the stepper on the left side responsible for the X-axis. I moved it directly to the x-axis and cut a plate for 4 wheels (there were 3 wheels by default). By attaching the stepper to the plate and placing it together with the laser, the photos have become perfect without banding. Banding, i.e. vertical or horizontal lines. Everything works perfectly at this point. I am very pleased with the machine. As standard, the ceramic tiles can be made at a speed of 1200 mm/min.

Now, after modifications, they can be made at a speed of 2400 mm/min. So I speeded up my work very cheaply x2. By default, such a tile takes 1h: 55 min at 318 dpi. 10x10cm.

Currently, tile 10×10 takes me less than an hour without losing any detail. The new version of the TTS-55 has an even smaller dot than its predecessor TT-5.5S. On the internet, you will find tons of free designs to be printed on a 3D printer. Which will easily fit your TWO TREES thanks to the use of 20mm x 20mm profiles.

Now, after applying the modification only with the cut of the appropriate plate to hold the laser and the stepper on the x-axis and printing the belt tensioners, I am the happy owner of this machine.

Remember, working with lasers means patience and persistence. Learn slowly and develop your knowledge and it will certainly speed up your work with your machine.

At the End

Thanks for the content and review by John Smith. We believe with all the detailed information provided and the hands-on experience share by John, it would not be a very difficult task to choose the right machine for your projects. If you have any questions or want to learn more about laser engravers, please do not hesitate to contact us or leave a comment.