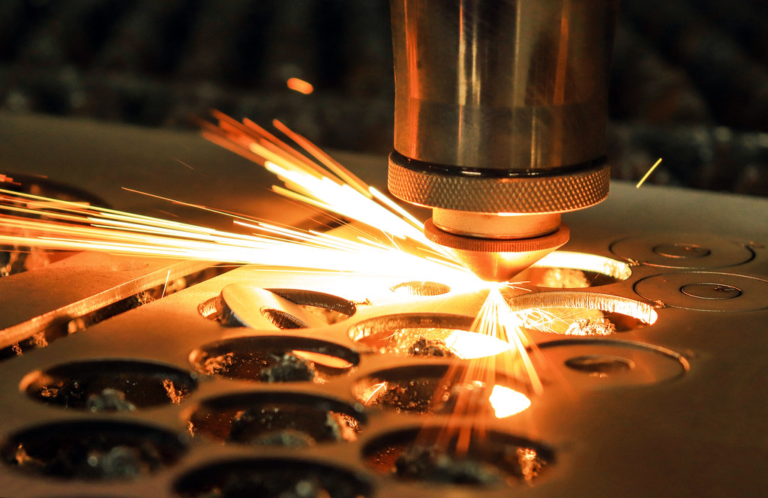

Have you ever encountered nozzle leakage which appears like the picture below. It is a problem that seems t0 be normal while using your 3D printers, especially when you’ve been using it for a while. However, it’s not a serious problem and can be dealt with easily. In this article, you will get the steps to solve the nozzle leakage.

Tools to use:

Pliers, open-ended wrench, hexagonal wrenches of different sizes, tweezer, steel brush and a lighter (or any tools you prefer).

Steps to deal with the nozzle leakage:

Step 1: Pull out the Teflon tube and remove the extrusion head.

Step 2: Unscrew the top screw on the cooling block, and remove the hot end.

Step 3: Click on the screen to heat the hot end.

Step 4: After reaching the temperature, use tools to clean up residual filament. Note: Do not touch the hot end by hand in the following steps to avoid scald.

Step 5: Remove the nozzle and throat.

Step 6: Residual filaments inside the aluminum block also need to be cleaned up.

Step 7: After cleaning, retighten the nozzle and throat.

Step 8: Turn off heating and wait for cooling.

Step 9: After the temperature of the hot end cools down to the room temperature, reinstall the hot end into the extrusion head and tighten the set screw.

Step 10: Replace the extrusion head and insert the Teflon tube. Note: the Teflon tube should be inserted into the bottom with force.

Hopefully you found this useful!