After all these years of development, the best home laser cutter machine is no longer an exclusive tool for industrial production but also a preferred option for home business and personal hobbies. If you are looking for a laser machine to expand your tool collection, you are in the right place to find this post.

To ensure you get enough information to make the right choice, this post would cover what you can make with a laser cutter, what makes the best home laser cutter machine, what’s the best laser cutter machine, and how much is the machine cost.

What Can You Make With A Home Laser Cutter Machine?

Major Functions of A Laser Cutter

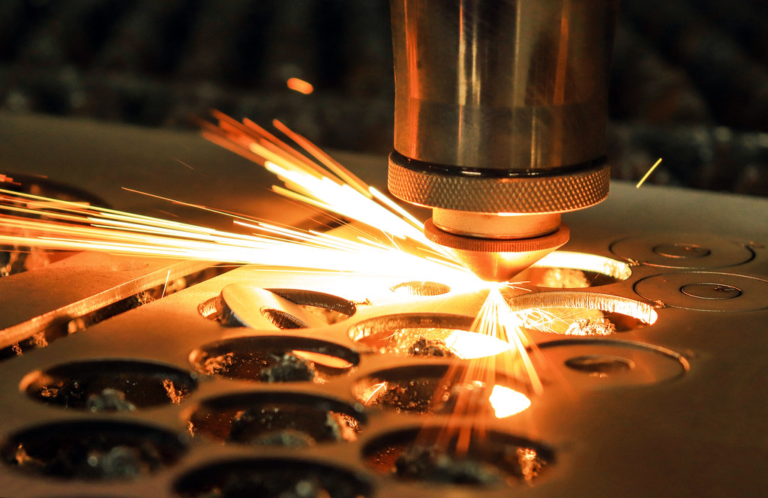

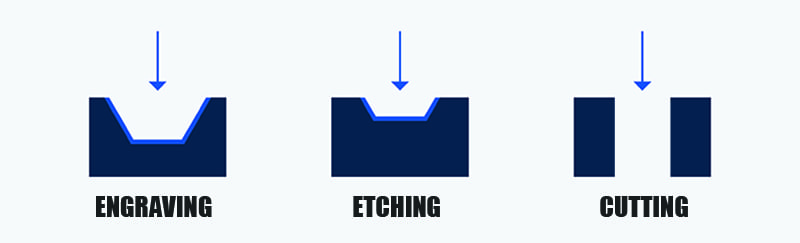

A laser cutting machine is a powerful tool to achieve different applications and functions. Depending on different materials and thicknesses, there are three major functions of a laser machine would be cutting, engraving and etching.

- Laser Cutting: Laser cutting is widely used for DIY and home business projectors.

- Laser Engraving: Laser engraving uses the highly-focused laser to vaporize the surface of a material and create a cavity of an image and pattern that is noticeable to the eye and touch.

- Laser Etching: Laser etching uses the laser to melt the surface of the material and its depth is usually no more than 0.001″. Compared with laser engraving, laser etching is usually used for hard materials like metal or glasses.

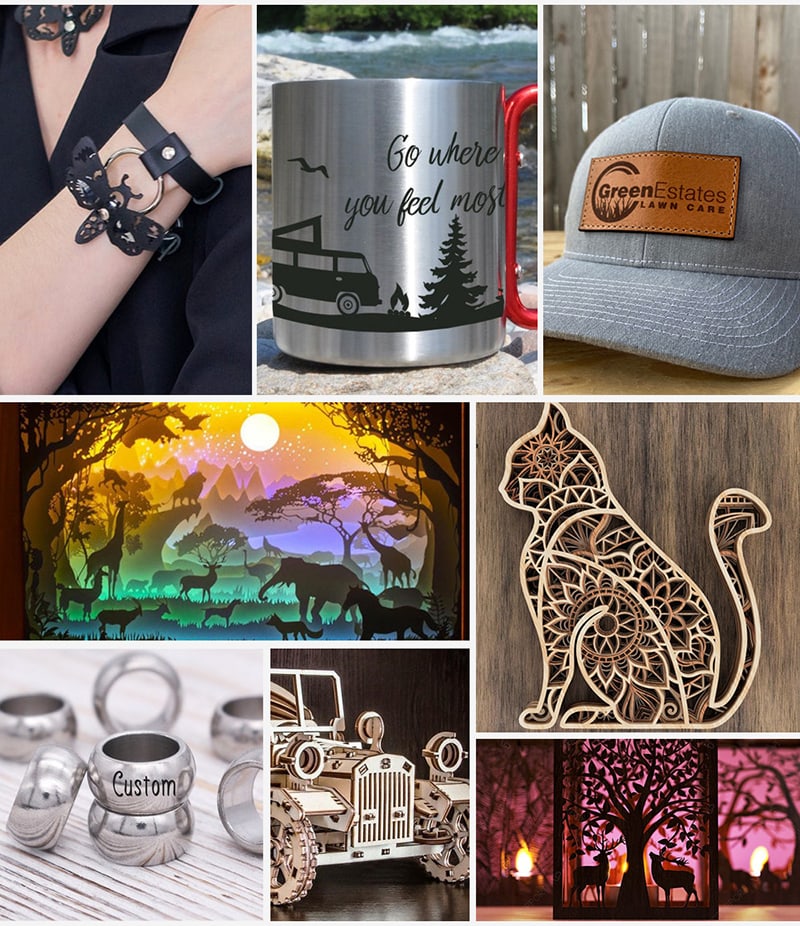

What to Make With A Home Laser Cutter Machine?

Since a single laser cutter machine could perform cutting, engraving, and etching, it provides the users endless possibilities to create projects with single tech or all tech combined. Before we list some interesting projects to start, feel free to check our previous posts “Engraving On Wood Ultimate Guide” and “Can you make money with TS3 laser cutter & engraver?” to find out some project ideas you can accomplish with a laser machine. Here is our list of top ideas to create with a home laser cutter machine:

- Customized Promotion Gifts

- Home Decoration Accessories

- Photoengraving

- Wall Arts

- Customized celebration and event products

- Mobile phone case

- Bookmarks

- Business cards

- Signboards

- Jewelry & fashion accessories

- Leather purses and bags

- Model making

Where to find laser engraving and cutting ideas?

There are many websites providing free or paid files for laser engraving and cutting. We have organized a post and listed the top 13 websites where we find files for our laser cutting and engraving projects. Here is a brief table for the websites:

| Website | Costs | File Format | File Quantity | Registration |

|---|---|---|---|---|

| https://3axis.co | Free | BMP, CDR, DXF, DWG, PDF, STL | 20,000+ | Not required |

| https://laser-templates.com | Free & Paid | AI, CDR, DXF, EPS, PDF, SVG | 5,000+ | Not required |

| https://www.thingiverse.com | Free | AI, BMP, CDR, DXF, PDF, STL, SVG | 4,000+ | Not required |

| https://www.librarylaser.com | Free & Paid | AI, CDR, DXF, PDF, SVG | 1,200+ | Required |

| https://3dsvg.com | Free & Paid | SVG | 740+ | Required |

| https://www.freepatternsarea.com/free-projects | Free | DXF, DWG, EPS, PDF, PNG, STL, SVG | 200+ | Not required |

| https://www.ponoko.com/free-laser-cutting-files-templates | Free | EPS, PDF, SVG | 200+ | Not required |

| https://www.festi.info/boxes.py/?language=en | Free | AI, DXF, G-code, PDF, PLT, PS, SVG, SVG_Ponoko | 200+ | Not required |

| https://www.vecteezy.com | Free | AI, EPS, JPG, PDF | 10,000+ | Not required |

| https://www.makerunion.com | Free | DXF | 230+ | Required |

| https://www.etsy.com | Paid | AI, CDR, DXF, EPS, PDF, SVG | 63,000+ | Not required |

| https://sofontsy.com | Paid | SVG, PSD, PNG, EPS | 100,000+ | Required |

| https://thehungryjpeg.com | Free & Paid | DXF, EPS, JPEG, PNG, SVG | 100,000+ | Required |

What Makes the Best Home Laser Cutter Machine?

Through the rich collection of laser engraving, cutting, and etching projects seem to be quite alluring, choosing the right tool to achieve the optimized result could be a bit challenging. To make it simple, we list 7 factors here that we consider the most important concerns when buying a home laser cutter machine.

1st: Power

Power is the most important one among all factors. Before we go further, please be clear that power is a general term that could either refer to the input power for the whole machine, the working power of a laser, or the power of each part. Why should I raise this topic here? The market is full of machines with wrong power ratings. Many suppliers claimed their machines as 40W but the truth is the laser power might be only 10W or less. The working power of a laser has a direct influence on the engraving or cutting ability of a machine (this also includes what materials and thicknesses a machine could process.).

Apart from the laser power, the overall power of a laser machine would also have a great impact on its performance. Taking our TS2 laser machine as an example, the 24V 4A input settings allows the machine to get an overall power of about 90W, which means it could distribute more power to all the stepper motors for faster and more smooth movement of the X-axis and Y-axis to save your time.

2nd: Accuracy

Accuracy could be a matter of engraving/cutting success or failure, this is especially true for functional parts. If you are running a home business with laser machines, accuracy might even be your top concern as any mistakes or imperfections could be loose of orders. Even if you use a laser machine for a personal hobby, a higher precision would bring more delicate details to your artwork.

3rd: Portability

For a home laser cutter machine, portability could also be an important factor. If you are checking this post, you might be looking for a portable machine to place in your house without taking up extra space. Off course, if you have a workshop and space isn’t a problem for you, you could get a larger machine with more functions and features. However, for a bigger and heavy machine, it would be difficult to relocate it once set up.

4th: Safety

For a laser machine used at home, safety is an inevitable issue to consider. Laser light is a form of high-density energy which could easily burn stuff and cause a fire. Thus, it would never be too careful to take some safety measures to ensure a fire is extinguished at its very early stage.

Another safety issue with a home laser cutter machine would be the toxic fume and smoke. Though the laser technology enables users to use various materials for different projects, there are many materials that would generate toxic fume and dust which are considered health hazards. Here is a short list of materials that should be avoided to processed without sufficient protection:

- Leather and artificial leather that contains chromium (VI)

- Carbon fibers (Carbon)

- Polyvinyl chloride (PVC)

- Polyvinyl butyrale (PVB)

- Polytetrafluoroethylenes (PTFE /Teflon)

- Beryllium oxide

- Any materials containing halogens (fluorine, chlorine, bromine, iodine, and astatine), epoxy or phenolic resins

If the above materials are in your material list or you are not sure about them, it would be highly recommended to buy a machine with a proper enclosure or ventilation system. You might also choose to buy or DIY some separate parts for your machine.

5th: Supported Materials

For DIY users, the material would usually not be limited to a certain type. Thus, a laser machine with a rich collection of supporting materials would stand out among its competitors. For home business owners, if your business involves only a limited number of materials, it’s vital to check and confirm with the seller if your materials could be processed properly. Most laser machines in the market would share the same material list but with different power settings and technologies, the thicknesses for different materials that could be cut would differ a lot.

6th: Versatility

There are many cases where you might need some advanced features and functions to achieve some complicated projects. One of the most popular and demanding features of a home laser cutter machine would be cylindrical laser engraving. This feature enables users to get perfect patterns and images on the carved surface including tumblers, baseball bats, pens, or other cylindric objects. In terms of versatility, the other concern might be the software the machine could use. LaserGRBL is the free and basic software that could work with most laser cutters. Lightburn on the other hand is a paid software with some advanced features. If you are using Lightburn for your projects, make sure to check if the laser machine is compatible with it.

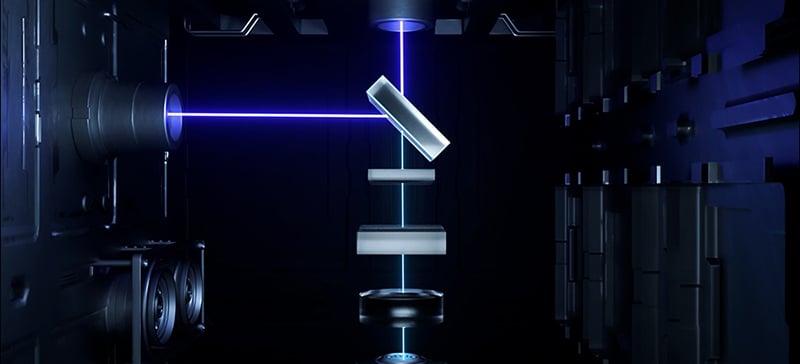

7th: Diode VS CO2 vs Fiber

When talking about laser cutting, one most debated question is the choice between diode laser and CO2 laser. In fact, diode, CO2, and fiber are three major laser technology in the market. The fiber laser cutter is usually used for industrial production with extremely high costs. Thus, for personal hobbies and small businesses, users would prefer choosing a diode or CO2 laser cutting machine. CO2 is featured for its high power but bulky size, vulnerable construction, high costs, and difficulty to use. However, a diode laser machine is known for its durable application, lightweight design, ease to use, and low costs. You may find a comprehensive comparison between these three laser technologies in our previous post.

8th: Price to Value

Price would always be one major concern when making any purchasing decisions. However, price should not also be considered along without talking about quality and performance. The best combination of price, quality, and performance would be the best-value option. Before doing in-depth research on all product options, it’s wise to set a budget and expectations for the deal. How much would you like to pay? What functions and features are essential? List all product possibilities and combo to check which product fit your lists best.

What Is The Best Home Laser Cutter & Engraver?

With all factors taken into consideration, the best home laser cutter machine of this year from our product range would be the TS3 enclosed laser cutter. TS3 is a powerful laser machine designed for use at home at its very first stage of product design and development. Here are reasons why TS3 is the best home laser cutter machine to have.

1st: 10W Super Power Design

With the unique and advanced technology, TS3 combines lasers from two separated 5W diodes into one powerful 10W laser to cut through 8mm plywood with a single cut. Compared with most market competitors to cut 3mm wood, its superpower design makes TS3 stand out in the fierce competition.

2nd: Accuracy

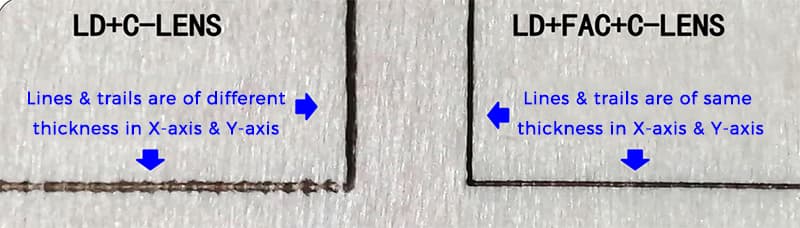

What’s more, the LD+FAC+C-lens technology is much more efficient in power conversion and generates a more concentrated 0.08mm laser spot. What’s more, the 0.08mm laser spot is not only smaller in size with a higher energy density but also creates even trails of the same size in both vertical and horizontal directions (most lasers would have different diameters and sizes in these two directions.).

3rd: Portability Enclosed Design

As a laser cutter machine designed for home use, TS3 is enclosed into a metal housing that is durable and sturdy. The whole machine is light in weight and compact in size which enables the machine to be moved and relocated easily with bare hands. The simple and clear design also makes it easily fit in the environment. You can either place it in your living room, study room, your garage, or workshop as you like without taking up extra space.

4th: Multiple Safety Designs

Safety is of top concern while designing the laser cutter machine for home use. To ensure safety at the highest level, we have added a few settings and designs to the machine.

1st: Protective Cove

As the laser light possesses risk and might cause permanent harm to the eyes, it’s always recommended to wear protective goggles when operating a laser machine. It is for this reason that we also packed one goggle with the machine. What’s more, we used a protective cover for the window to filer all harmful lasers from the eyes thus users could enjoy laser cutting with friends or family members together without wearing goggles.

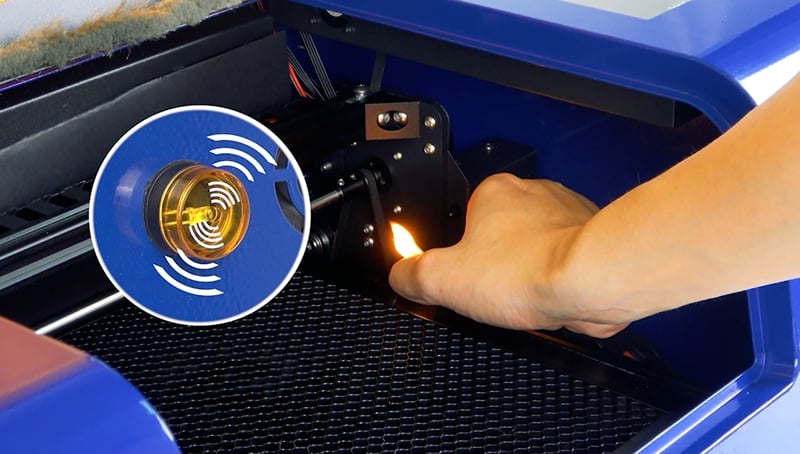

2nd: Built-in Flame Detector & Fire Alarm Buzzer

To deal with the fire hazard, we designed a fire alarm system for the laser cutter machine. To enable a fire to be detected at its earliest stage, the built-in flame detector would find any flame with an infrared sensor.

Detecting a flame is one thing and stopping it from developing into a fire is another. To ensure each hazard is taken care of, once a flame is detected, the fire alarm buzzer would sound the alarm. And the metal-enclosed housing would contain the fire inside the box and stop the fire from spreading anywhere else.

5th: Rich Collection of Supported Materials

TS3 machine also supports various materials for engraving, cutting, and etching. Please be noted that most metal materials with coated or electroplated surface treatment could be engraved or etched. Transparent materials like glasses usually require a color painting before engraving or etching.

6th: Versatility

Apart from the basic functions, there are also some extra functions and features that add extra points to TS3 laser cutter.

1st: Built-in Rotary Attachment for Cylindrical Engraving

With years’ experience in the laser industry, we understand the importance of cylindrical engraving, and our users would like to have this feature included. Thus we add the built-in rotary roller beneath the cutting table. What’s more, we also add a rotary engraving function in the software and an extra rotary switch on the back panel, so users could easily switch between normal engraving and rotary engraving.

2nd: Extra Ventilation Fan & Pipe to Upgrade Safety

The dust and fumes generated while cutting and engraving are also one annoying issue, not to mention the health hazard of toxic fumes. Thus an extra ventilation system would be really important if you are setting up the machine in your house. In this regard, TS3 is designed with a built-in exhaust fan and an extra exhaust pipe. It’s ideal to place the machine near the window and to exhaust out all smoke or fumes from the window.

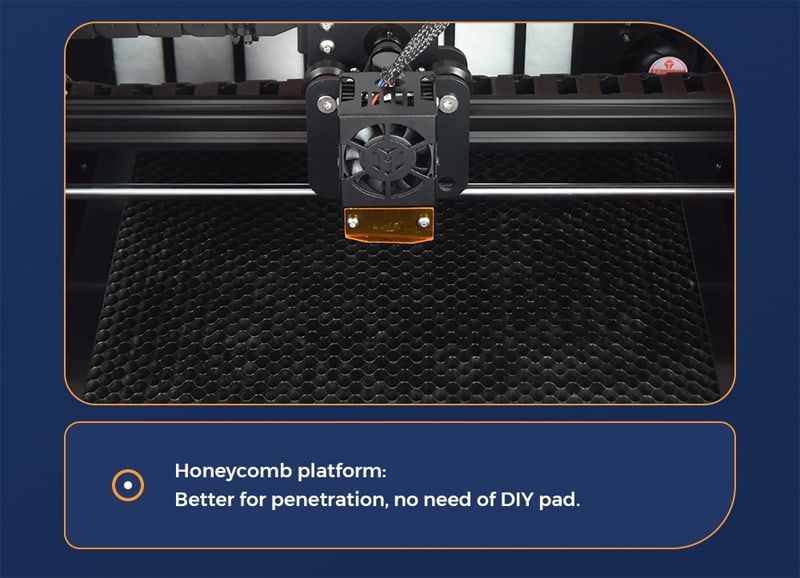

3rd: Built-in Honeycomb Workbench

The purpose of a workbench is to protect your table from getting burnt and to provide more airflow for cutting. The honeycomb workbench is built with aluminum material with a hollow design. Its hollow design would make laser cutting easier and leaves fewer burn marks. You might find there are also workbenches for laser cutting sold on amazon which might cost over $60.

7th: Best Value Home Laser Cutter Machine

As the best home laser cutter machine, TS3 is also the best value product for customers. Apart from its 10W laser power and 0.08mm accuracy, the extra functions like rotary roller attachment and extra workbench add extra value to this machine. If you are looking for a versatile device to meet all your demands with a single machine, TS3 would definitely be a good choice to give a try.

Specifications

- Engraving Size: 300*200mm

- Laser power: 10W Compressed spot laser

- Laser wavelength: 445±5nm

- Output power: 35W-40W

- Material: Aluminum profile + metal

- XY Axis Positioning Accuracy: 0.1mm

- Engraving accuracy: 0.08mm

- Engraving speed: 10000mm/min

- Engraving method: USB/APP/Online/Screen Operation

- Engraving materials: Stainless steel, Plastic, Wood, Leather, Sponge paper, Alumina, Spraying layer, etc

- Document format: NC、DXF、BMP、JPG、PNG、GCODE

- Engraving mode: Image carving、Test carving、Scanning carving、Contour carving、Pixel carving

- Support language: EN, RU, ES, FR, IT, ZH-CN, ZH-HK

- Support system: Windows, Mac

- Support Software: LaserGRBL\Lightburn

- Continuous working time: ≤12hours

- Machine Size: 570*430*270mm

- Package Size: 630*500*330mm

- Machine Weight: 14.4kg

- Package Weight: 16kg

Conclusion

Finding the best home laser cutter machine for home use would be a challenging task as the market is full of misleading information. With the 8 factors provided, hope this post could help you clear some doubts and make the right choice. If you do not have any laser models in mind, TS3 could be your first machine and your money would be paid off really soon.