Though the 3D printing technology could be traced back to 1980s, it was considered an idea in science fiction for quite a long time. Then the later social buzz on 3D printing makes people hold either a positive or negative view without seeing the whole picture. To realize the full potential of 3D printing technology, it’s vital to have a clear understanding and avoid some of the biggest misconceptions about 3D printing. Here are the top 15 misconceptions:

1) 3D printing will replace traditional manufacturing

3D printing has radically changed the manufacturing methods industries including in-ear hearing aids, dental restorations, orthopedic implants, orthodontics, and pipelines for aircraft environmental control systems and has permanently changed the industrial structures. However, 3D printing won’t replace the traditional manufacturing method in the near future due to its limitations. The traditional manufacturing method of using modeling tools would still be a more cost-effective choice for mass production for a very long time to come. The main reasons why 3D printing can hardly take over the market is as follows:

- Relatively low production speed: a single model even with a small size would take hours for printing.

- Limited material options: There are still lots of materials that could not be used for 3D printing.

- Higher unit costs: The overall unit cost for 3D printed items are much higher than those produced with traditional manufacturing.

2) 3D printing will cause more unemployment?

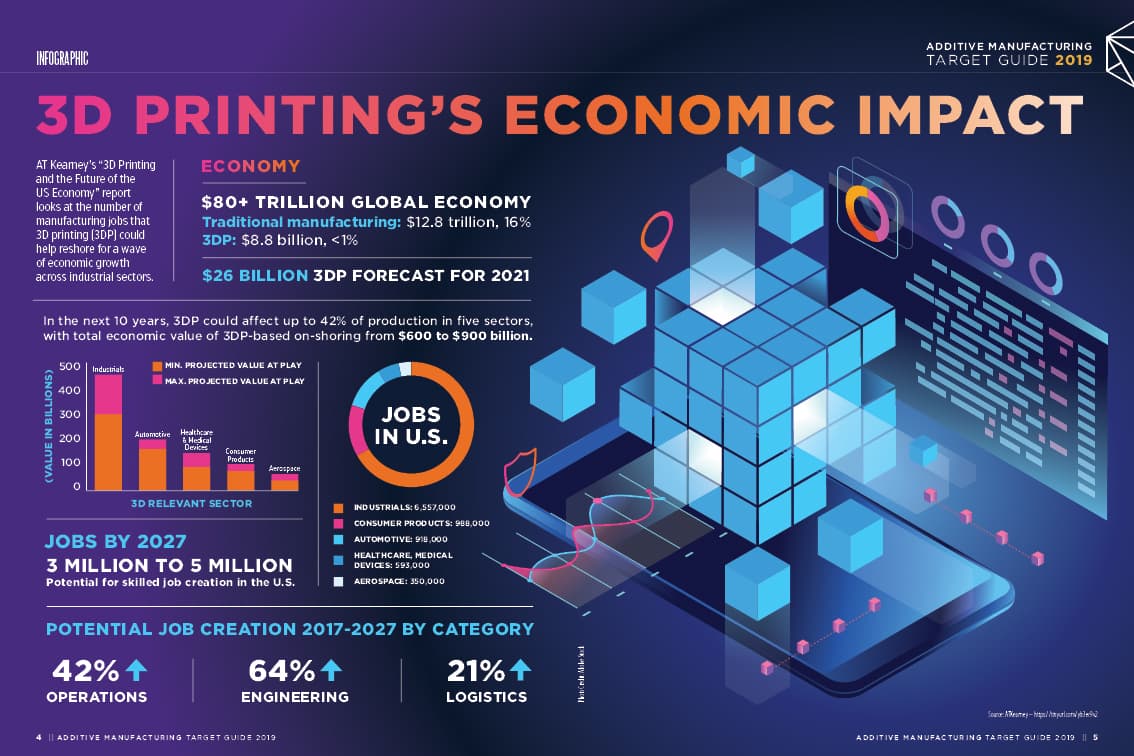

The emergence of 3D printing is revolutionary, but at the same time, many people worry that 3D printing will steal their jobs. The logic behind is that 3D printing would enable production without assembly and remove parts suppliers out of the supply chain which would lead to unemployment. However, because of its limitations and failure to apply it to mass production,3D printing technology presents fewer threats to these labor-intensive industries (the real challenge might come from artificial intelligence technology and industrial robots ). On the other hand, 3D printing can make it easier for people to turn their ideas into reality, thereby bringing more startup companies and more career opportunities. A recent study shows that by 2027, the potential job opportunities generated in the U.S. alone would be about 3 to 5 million.

According to the latest report by the France’s Employment Policy Council, less than 10% of jobs may be threatened by the rise of automation technology. New technologies may significantly change the way of about half of existing jobs be done and make many trivial tasks more interesting and efficient. The transformation will create many job opportunities that will make up for potential unemployment, and it depends on the actions of all economic participants, citizens and the government.

3) 3D printing is only for making prototypes

FDM 3D printing is first widely used and popular for rapid prototyping. Many factories realized its unique advantage and utilized 3D printing technology to shorten developing time and lower the costs for new product development instead of outsourcing help from the service providers. It’s no doubt the 3D printing technology has outstanding advantages over traditional manufacturing, but the wide application of 3D printing in our daily life or various industries should not be overlooked as well. After years’ improvement, 3D printing technology has become a far more helpful tool to produce functional parts and conduct small batch production in various industries. 3D printers could print everything you can imagine is another misunderstanding on 3D printing technology which also proves that 3D printers are no longer a toymaker and has wide application far beyond imagination.

4) 3D printing is only for professional industry

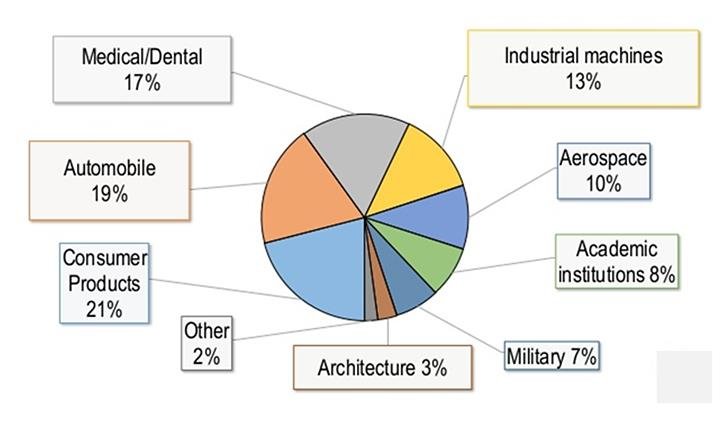

Though 3D printing technology plays a more and more important role in architecture, auto manufacturing, its application is not limited to these areas. The rising of 3D printing technology is due to the widespread and expanding of the consumer 3D printers market. More and more people have developed 3D printing as a personal hobby or a business idea. Many 3D printer factories, government organizations and training organizations have come to notice the big market potential and opportunities and have been working together to include 3D printing into online and offline training programs to enable more and more people to be ready to use 3D printers for both personal creation or professional application. The truth is that consumer 3D printers have enabled people with no background knowledge to enjoy the convenience of the technology. No matter you are DIY enthusiasts, with a great passion for collection, or want to need small tools to make life easier, 3D printing is an easy solution for you.

5) 3D printing produces only low-quality parts

This misconception is because of the fact that the most available 3D printers in the market are consumer-level FDM 3D printers which are not designed for the quality level that is expected from traditional manufacturing. Most 3D prints you see on social media might be created with these 3D printers with fewer details and lower precision. There are also product options that provide more details and higher quality levels but with a different budget level.

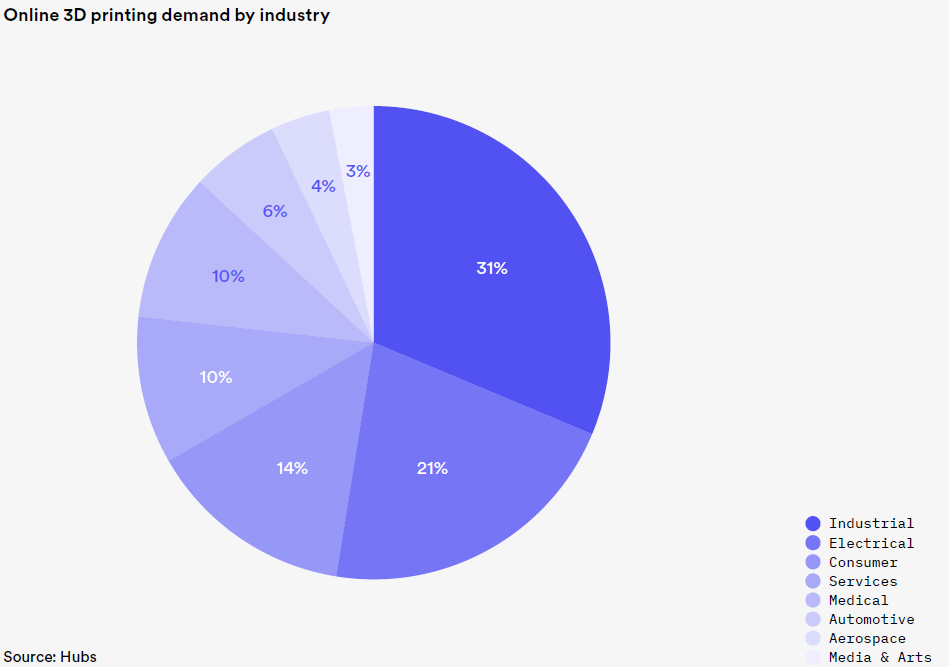

The fact is consumer market is only a small portion of the overall 3D printing market. Following is the latest report on the 3D printing industry, the industrial and electrical application of 3D printing tech covers over 50% of the online 3D printing market share. Many industries including aerospace are regarded as industries with the highest demand for quality and precision and industrial 3D printers in these areas have successfully completed the task. Thus it would be safe consumption that the ideal 3D printing produces only low-quality parts is far from true.

The range of high-end additive manufacturing production systems is actually more likely to improve on the quality of conventional products – with super-strength internal structures, extraordinary geometries and lightweight builds all possible. By adjusting aspects like interior density, orientation and material, 3D-printed parts can be as strong or as flexible as required, with surface finish improving all the time. Some new methods like Digital Light Synthesis help generate elaborate products from the start. because the process does not require layering. The outcomes are monolithic meaning that they come out as a smooth liquid.

6) 3D printers can create only small parts

One limitation for 3D printers is printing size. For most desktop 3D printers, yes, they could only create small parts. However, the truth is much more complicated as there are also large-scale 3D printers in the market. If you are working in the 3D printing industry, you might have heard lots of news on the 3D printed house and communities. 3D printed house is only an example of 3D printing social media buzz. There have been many 3D printed buildings, bridges and other large-size prints all over the world.

7) 3D printing design is easy

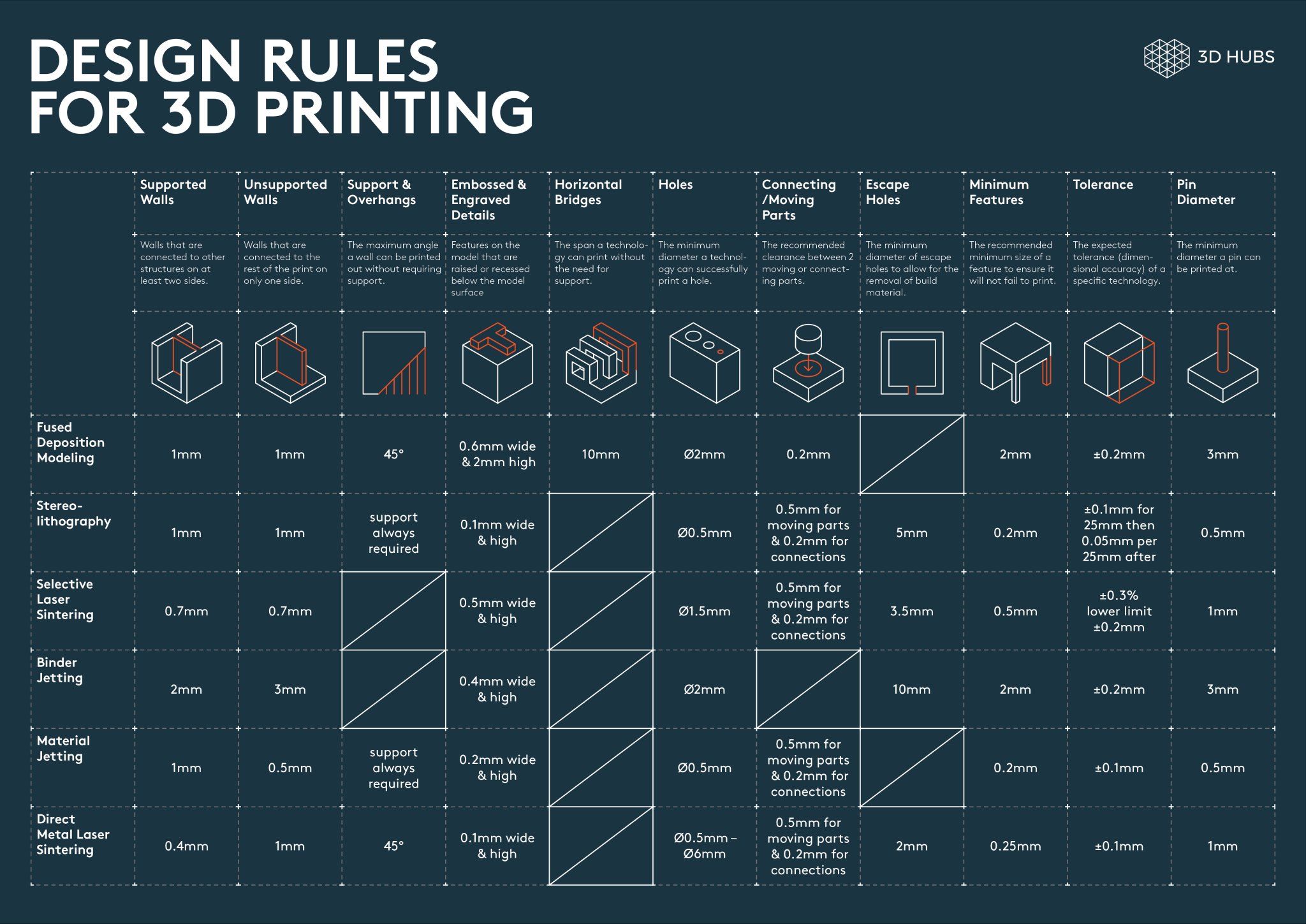

This misconception could easily lead to printing failure. Just like any architectural design is not only about presenting the most astonishing and pleasant visual effect but also providing a guide to bring the design into reality, 3D printing design is not an easy job. One can hardly take a design program and create a part with a few clicks of their mouse. He has to consider the use of the product, constraints of the materials and processes, and the interaction of the mating parts and the assembly of the product. In FDM 3D printing, you might need to add visually useless supporting parts to prevent printing failure, add raft & brim to stop warping (Check our post “3D Printing Warping- 10 Tips to Prevent 3D Print from Warping” to find more details), use different filling structure and density for different prints and avoid certain designs to get solid and decent prints. Whether you design for yourselves or download design files from websites, it won’t be more careful to make a close look and study on the design before start printing. Following is a guideline for 3D printing designing from 3D Hubs.

8) All CAD files are ready to be 3D Printed

Most 3D printers need a file to start printing and STL is the most common format. It can easily be saved and converted into G-code which is readable for 3D printers and work as instruction for 3D printing with the assistance of a slicer (slicing software). Unfortunately, not all design file is in STL format and sometimes the design program may not properly convert the file to the STL format. It is important for one to be aware that the file converts properly to an STL format. This will help ensure that the 3D printed part is not faceted.

9) With 3D printing, complexity is free

Compared with traditional manufacturing, AM technology can still provide a high degree of freedom in design and can realize many applications that were not possible to manufacture in the past. “Complexity is free” is a phrase commonly heard within the industry. It refers to the ability to use 3D printing to produce objects of any level of complexity. Since 3D printing requires no assembly and complex products could be easily created if properly designed.

However, this does not mean there is no limitation with design complexity for 3D printing. AM designers in many companies are required to receive training to learn the feasibility and limitations of the technology and how to successfully design, optimize and apply AM technology before starting work. Some basic design principles to follow would be as follows:

- pay attention to the wall thickness and gap distance

- designed with as low an aspect ratio and surface resolution as possible to ensure a stable production cycle

- avoid unnecessary complications

10) 3D Printing is Only for Nerds

3D printing is used to be technology available only for people with rich background knowledge and many of them are nerds. However, 3D printers have been made easier and easier to use and it has become a more available hobby like wood carving, paper cutting or more common DIY activities. 3D printers are just creation tools to bring ideas to life and does not require nerds’ mind to use them.

11) 3D Printers can print anything—even fully functioning human organs!

Many believe that with the design file, one can print anything he can imagine. One hot topic regarding this is when would 3D-printed human organs be available. Though biomaterials that make up human tissue can be 3D printed and are often used in testing drugs and other treatments, fully functioning human organs are far too complex for current 3D Printing technology.

Except for human organs, there are many objects that are not printable due to the 3D printing limits. For example, to print an object, you need its 3D data to build 3D models, and if you do not have any 3D model design experience, you might find a limited number of models suitable for your projects. If you get the right 3D model file, you still need to find the right consumables for the model.

12) Soon Every Home Will Have a 3D Printer

This reminds me of the fact that the prediction of “every home will have a computer” was once questioned by skeptics. However, 3D printers are quite different compared with computers. Before the merge of computers, people wrote, communicated with others, managed documents, enjoyed music, organized photos and engaged in accounting and research work. People now are still doing these things but with the assistance of computers.

As for 3D printers, most people are not product designers, inventors, or DIY enthusiasts, thus 3D printers can hardly change their work and lifestyle. The future of 3D printers seems to prosper in local 3D printing stores, online printing service providers, and online reselling of 3D printed parts.

13) 3D printing only requires the push of a button.

Maybe most advertisements and propaganda on 3D printing only tell you how products are created like magic with this amazing technology after the single push of a button and do not even bother to tell the hardworking requires to get everything prepared before pushing the button. It’s not plug-and-play like you heard.

Sure, you can purchase a 3D printer and start printing right away but you won’t get anything without a strategy and plan. Before printing, you need prepared 3D model files or related information, modify product models and optimize structure (most 3D printers require support structures), make customized settings (layer thickness, temperature, speed, etc. ) for different materials and designs. Any error in hardware or software would end up with poor prints or printing failure. If you have no experience with 3D printing, it would be highly recommended to spend some time learning how the 3D printers and software work.

14) The costs for 3D printing are high.

The major costs for 3D printing are costs on 3D printers, consumables and 3D designing. For consumer 3D printers and consumables, there are many affordable product options on the market like BLU-3 which only costs only USD199. As for costs on 3D design, you can either download free online courses or pay to join a training program if you like.

On the other hand, for manufacturers, a 3D printer is an investment with a high return on investment ratio. Traditional manufacturing usually relies on molding which is very costly in terms of price and time. This is especially true for small batch production and 3D printing technology gets rid of molding and maximizes the return on investment.

15) The 3D printing manufacturing speed is very fast.

The 3D printing system forms a continuous layer of material through deposition, melting, solidification, or lamination to build parts. The thickness of these material layers is usually 0.025-0.254 mm, so thousands of layers are often required to form the entire part. For large-volume modeling, determining the scope and curing each layer of material can be quite time-consuming. The processing cycle between the various layers also increases the manufacturing time. The 3D printing process of heating and forming with a modeling cylinder takes a lot of time for preheating and cooling. Some 3D printing processing tasks require several days to complete all the necessary steps.