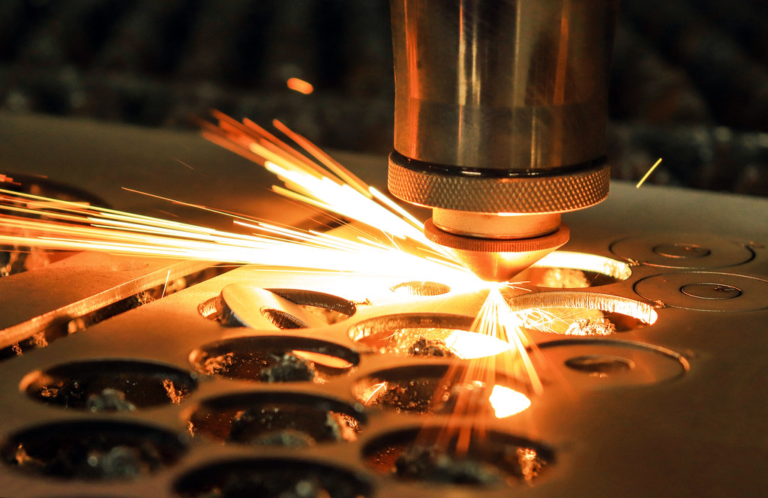

Compared with most other cutting techniques, cutting and engraving projects with laser are more precise and cleaner. And it requires less deburring or finishing after cutting, though this also depends on the materials you cut. Prices or costs of laser cutter vary greatly owing to the various design, type, and performance of laser. A new laser cutter may cost from $200 to $1,000,000.

Therefore, it is significant for you to find a proper balance between your needs and budget.

What reasons you need a laser for?

First of all, to decide what laser cutter is suitable for you, we need to identify your needs.

Although the range of materials may be quite wide, the machines with lower laser output fail to cut metals. Lower end of the charging spectrum is an appropriate option for DIY enthusiasts looking a laser to cut, engrave or mark on non-metals or soft metals.

For example, TwoTrees TT-5.5S as a 5.5 watts laser cutter, it could meet most basic requirement of most daily projects for beginners.

Cutting larger objects will need a larger machine. However, high wattage laser and large cutting machines are usually much more expensive than entry-level ones. You can pay anywhere from $4,000 to $15,000 for them. But to some extent, purchasing a high watt laser cutter can be more cost-effective for prolific projects.

If you do not know what you plan to cut, or you want to cut as wide as possible of materials, a higher watt laser is better if your budget permits. This type of laser is sufficiently strong to cut and engrave almost anything, providing the flexibility you need.

Different prices for different laser

You might be wondering about the cost ranges of diode laser, CO2 laser machines or fiber lasers.

Before thinking about choosing which type, you need to consider some main points firstly:

- What materials do you want to cut?

- What are the laser power?

- What sizes do you need?

Laser cutting with fiber lasers is much more energy-efficient, accurate, but more economical for luxury industries. Fiber lasers usually cost in the range of $20,000 to $45,000.

If you are looking for a machine to produce parts for your DIY artworks, you don’t have to spend that much. However, the prices of laser for such use like diode laser, CO2 laser only start from $200 and go up to about $10,000, which is much cheaper than a fiber laser. This is a great site to get recommendations according to your budget. The materials are a deciding factor when choosing between different types of lasers. Just make sure the machine is able to cut the materials in the size you need.

Another thing to keep in mind is the laser power. A golden rule here is that doubling a laser’s power doubles its cutting/engraving speed. Power is also the vital parameter that determines the thickness of cutting. High-quality cutting is only allowed by a machine with enough power.

We would not advise to make the choice based on the cost only, as the cost also tends to reflect in the reliability. At the same time, going for the highest possible grade would probably need sufficient usage of the machine to justify the costs.

If you have a limited budget, diode laser cutter with relatively higher power like TwoTrees’ TS3 (10 watts) are perfectly good for most DIY projects.

By the way, the Kickstarter project of TS3 is ongoing with economical cost from $569 to $769. +Link

|

|

Buy a new one or used one?

This is again a question that does not have a right or wrong answer. It is definitely possible to find a good bargain on the market, especially when it comes to simpler machines used for DIY projects.

Brand new machines also comes with a guarantee. New machinery also means new technology, resulting in quicker turnaround times and more profit.

So it may be wise to consider what do you need the laser for – is it for fulfilling your own needs sparingly or does your business depend on it?

Conclusion

The prices of laser cutter vary greatly from $200 to $1,000,000. The most important considerations must be these 3 questions: What materials do you want to cut? What laser power is sufficient? What sizes do you need? Then you can buy one within your budge. Here is more details about laser engraver guide for beginner , feel free to check out.