3D Printing-Future of Manufacturing?

When first mentioned on a magzine issued in 1950s, 3D printing is considered as idea of imagination that would only be found in science fiction. It has been over half centry, the idea of additive manufacturing is still not quite well known among manufacturing industry. Even though many well designed 3D printers and brands are raising rapidly in marketing during past few years, many industry leaders still hold doubts about this new technology and waiting for all dusts to set down. However, as more and more successful stories about 3D printing company has been spred out, people start wonering is 3D printing the future of manufacturing?

What’s 3D Printing & how it works?

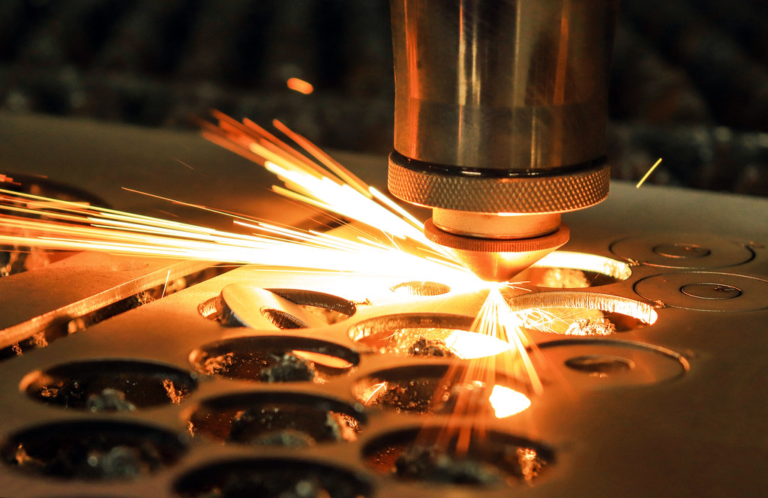

3D printing, also known as additive manufacturing, is the process of producing 3-dimensional objects from a computer file, where the part is built by adding material layer-by-layer.The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced cross-section of the object. 3D printing is the opposite of subtractive manufacturing which is cutting out / hollowing out a piece of metal or plastic with for instance a milling machine.

To complete the manufacturing process, following are something

- 3D Models (Thingiverse is the largest repository of free-to-use 3D models on the web)

- An SD card to copy 3D models you intend to print

- A 3D Printer (FDM 3D printers are most common ones in market )

- Base Materials (You may check here to find some available 3D printer filament in market)

- A Slicer (Cura, Simplify 3D and PrusaSlicer is widely used by designers)

Why 3D Printing?

The reason why some industry experts still hesitate to employ 3D printing into their daily producting is due to the assumption that the 3D printed parts cannot not meet their industry quality standard. This’s partially ture but 3D printers have developped and evolved so fast that 3D printing has been used to print parts for spaceship and Aerospace Station which have strict quality standard to every singal part or accessories.

However the reasons for 3D printing growing so fast during past decade is much more complicated, here are few obvious reasons:

Reason 1: Massive Customization

With traditional manufacturing processes, each new part or change in part design, requires a new tool, mold, die, or jig to be manufactured to create the new part. This is not only a matter of time and costs, but sometimes a matter of life and death for some projects. I have seen project been abandoned because impotant component cannot be produced within buget or replacement could not be found. However, 3D printing allows factory print almost anything out of 3D model design file that fits within its build volume.

Reason 2: Environmental Friendly

It’s quite common in traditional manufacture that leftovers and materials are cutted off and discarded away as factory can hardly find a way to reuse them for production. That’s a totally different story in 3D printing. There are many 3D printing companies now are collecting and recycling materials for printing. This could be a very promising and profitable solution for industrial waste recycling as tons of wasted production materials might be dumping to local garbage treatment station for paid recycling. What’s more, the way how 3D printing works ensures that there would be no more waste on material. Why? 3D printing use filament as base material. The 3D printing machine would take only exact quantity needed for printing thus there would be little problem with environmental protection.

Reason 3: Fast

Back to old times, developping new products or changing product design means piles of works to do and lots bill to pay. The process of negotiation and discussion on details for each part would be pretty frustrating.What’s worse, if you are not lucky, you might end up finding one part won’t fit other parts correctly. Rebuild the wrong parts might slow down your whole project for another 3 months for opening new module, sample shipping, and possible modification. Even if everything goes smoothly, your product enter into market one month later after massive production, your product might missed the peak season or out of fashion then.

With 3D printing, the whole process could be speeded up and completed within weeks and you might get a workable sample on hand and start your marketing campaign by then.

Reason 4: Afordable

Since 3D printing has not gained recognization as it deserves, many might have no idea about the costs. During past few years, the developent and spread of 3D printing technology enables 3D printer manufacturers keep their production costs much lower than before. One can easily get access to a desktop 3D printer at $200-$500 for DIY projects. If you are looking for a industry 3D printers, that might be a serious business decision to make. However, there are many 3D printing service company that might be happy to help with your industrial needs, don’t hesitate to contact them for a quote.

How 3D Printing Lead Munufacturing Into A New Ear

Rapid Prototyping: Any startup that trying to buil a new product or invent something new would need a working prototype to share with business partners, investors and end users. Many companies spend lots time and money working up models and testing prototypes. 3D printing provides a much faster and more cost-effective solutions for these startups. It’s also much easier to adjust the model or make changes before printing new prototypes.

Spare parts: For many manufacturers, producing and stocking spare parts is a risky chooice and holds up their capital. And if spare parts out of stock, the delay in assembly and shipping would impact customer relationship and brand reputation. 3D printing would be a very easy and affordable solutions to this issue. If you are not ready to include 3D printer into your machine list, you could also reach out to local 3D printing service provider for spare parts printing. However, it would be a reasonable decision to have one in long term if spare parts are very important part of your business.

Improve Your Products: Due to limitation of traditional manufacturing, there are many parts that could not be produced with traditional approach. With 3D printing technology get involved, many of these impossibles are now workable. Many improvements now could be achieved by making parts lighter or develop design that is too difficult to creat with traditional manufacturing. For example, you could add lattices to your product, or strengthen your 3D print using jigsaw structures. It is also really convenient to create objects in just one part. You may know it, but some intricate designs can be challenging to develop in only one part. But additive manufacturing technology allows you to do that.

Tooling: Rapid prototyping and product developing is only a small part of the view. If you search the internet, your might find some big name company has started to use 3D printing for tooling. For example, as a car manufacturer, Volkswagen Autoeuropa is using 3D printing for manufacturing some of its tools.The company estimates that thanks to 3D printing they saved 250,000€ in 2017. No matter what your sector is, reducing your tooling costs could be a huge asset for your company.

Conclusion

In spite of the fact 3D printing lack of more recognition, the manufacturing evoveling is happening without much propaganda. The practical application and ever-growing demanding assures a promising future for 3D printing. If it did not occur to you, it’s really a good time to start considering set up 3D printers for your production line. If you are not sure yet, please wait for our post regarding practical 3D printing startup ideas, you mind find your answers there.