Two Tree’s TTS-55 is a no-frills desktop DIY laser cutter with enough power to cut through an 8 mm thick sheet of light plywood and engrave various kinds of leather, wood, MDF, acrylic, cardboard, bamboo, anodized aluminum, stainless steel, plastic, paper, rubber, sponge paper, etc… Engraving works are more delicate. Similar to traditional power tools, you’ll need to buy additional safety gear before operating the desk DIY laser cutter TTS-55. It does not come with a fireproof base to sit on or any kind of ventilation.

This desktop DIY laser cutter TTS-5S is an open frame device with stepper motors mounted to the sides and belts to drive the X and Y movements. There’s no screen or buttons beyond the on/off switch, so you’ll need to hook it up to a computer running software such as LightBurn.

I tested the desk DIY laser cutter TTS-55 on some common items – light sheets of wood, leather and bamboo cutting boards. The laser performed excellently, giving effortless dark burns and slicing through thin materials with ease.

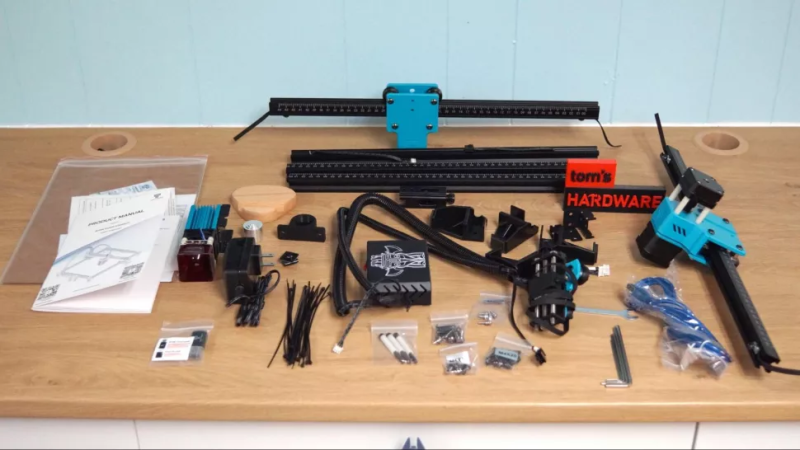

Unboxing the Desktop DIY Laser Cutter TTS-5S

The desktop DIY laser cutter TTS-55 comes with the tools to assemble the machine, a microSD card and adapter, and one pair of laser safety glasses (not shown). You also get a sample of cardstock and a blank wooden phone holder to engrave. The microSD card has a PDF copy of the manual, cutting and engraving files for multiple materials, and three sample images. It also has two software programs to operate the laser: LaserGRBL and a 30-day free trial of LightBurn.

Design of the Laser Engraver Machine

It is an open-frame, 5-watt laser engraver made of extruded aluminum with bright blue plastic accents. This desktop DIY laser cutter is a simple machine with no place to hide the cables – Two Trees keeps all the wiring neat and out of your way by running them through plastic hoses which you can strap in place with cable tiles during setup.

This laser engraver has three stepper motors for smoother control – one for the X movement and two for the Y movement. However, the Y steppers motors are slung low from the bottom of the frame, leaving no space for material to pass underneath. You could possibly raise the frame up with blocks under the feet, but it’s best to limit yourself to materials that fit inside the 300×300 frame. There’s an optional extension kit you can purchase that will increase this machine’s cutting area to 400×420 mm.

There is no screen or controls on this machine, only an on/off switch. The Two Trees TTS-55 must be used while tethered to a PC running software such as Laser GRLB or LightBurn, or operated via Wi-Fi with an optional phone app. I only tested the laser with a PC laptop, as Wi-Fi is spotty in my workshop.

You need perfect focus to get crisp lines with a laser, and that focus is achieved with the help of a metal shim. The shim is 23 mm tall, the exact height the laser needs to be from the surface you want to engrave. Slide the shim between the laser and the object you’re getting ready to engrave or cut, then adjust the height using a twist knob.

The laser can work on items as thin as paper and up to 5.5 cm thick. If you need to engrave thicker items, the machine can be placed on blocks if you provide them.

One thing I found odd is the lack of programming to send the laser home – which resets the machine coordinates to 0,0. Instead of entering a command, you need to turn the machine off, physically pull the carriage to the lower left corner of the frame, then turn it back on.

There is no exhaust fan on the Two Trees TTS-55 and it can get rather smokey, especially when you’re burning test patterns. You definitely need to run this with an exhaust fan or in a garage with the doors open.

Safety is a major concern when operating laser devices. It has included a transparent shield attached to the laser module to prevent you from looking directly at the laser beam.

Assembling the Laser Engraver

The Two Trees TTS-55 arrives in kit form and needs assembly – and a bit of patience. It should only take about 30 minutes to assemble, but that doesn’t include the time I spent rebuilding the machine after discovering that I had put it together backwards.

The pulley blocks are already mounted on the X-axis, and the timing belts are pre-threaded. The first thing I had to do was assemble the rest of the frame by bolting the two Y-axis onto the X-axis, forming a square.

Next, I mounted the feet with two screws each.

The X gantry is the fun part – I had to slide the laser’s carriage onto a fifth aluminum extrusion, then pull the timing belt into place inside the tensioner. Then you loop the timing belt around the stepper motor gear on the Y-Axis and screw the whole thing into place with long bolts that come up from the bottom. A second set of hands is really helpful here.

Now I was ready to screw the laser module into place, attach the motherboard’s case to the frame and run the wires. The wires are already inside lengths of black tubing and connected to the motherboard. The tubes are strapped onto the frame using handfuls of small zip ties.

The final step is plugging in the four wire connectors. These aren’t marked, so it’s a good idea to watch the laser engraver machine guide video so they are all pushed into the correct sockets.

Safety Precautions for the Laser Cutter TTS-5S

The laser cutter TTS-55 is a Class 4 laser that can damage your eyes and burn skin. It also produces smoke and fumes while engraving or cutting materials. You must take precautions to operate the machine safely. It is equipped with a transparent safety shield over the laser module, however there is a slight gap between the shield and the material. Because of this gap, you must always wear safety glasses that protect you from light of the 455 nm (blue) wavelength. A pair is provided with the machine.

Prevent pets and other people from observing the laser while in use.

Since the laser is literally burning material, never allow it to operate unattended and have a fire extinguisher handy just in case. A ventilation system is not included with this machine – you will need to either operate the machine in a garage, or provide a separate system to remove smoke from the room.

This is an open frame device and does not come with a base and should be placed on a fireproof surface. Comgrow sells a honeycomb panel with an aluminum plate(opens in new tab) made specifically for diode lasers. We’re using a piece of $20 fireproof cement board from the hardware store that covers the entire counter.

Some materials should not be burned with a laser due to their chemical makeup – they could melt, catch fire or produce toxic fumes. Dallas Maker Space has published a list of safe and hazardous materials to use with their laser. The list of no-nos includes plastics, fiberglass and certain foams.

The laser lens can get dirty from smoke and fumes. It’s a good idea to wipe it clean – while powered off and unplugged – before each laser session. If it’s allowed to become dirty, the laser will lose some of its capability. You can use any soft cloth for cleaning eyeglasses.

The Laser cutter TTS-5S: Software

The Two Trees TTS-55 comes with a free copy of LaserGRBL and a 30-day trial of LightBurn.

LaserGRBL is a Windows program available for free and allows for basic control of the TTS-55. Your computer will need to be tethered to the laser via a USB data cord (provided) during operation.

LightBurn is a complete layout, design and control software that operates on Windows, Mac OS and Linux. They offer a free 30-day trial of the complete program.

Two Trees TTS-5S: Engraving / Cutting

The ability to cut or engrave materials is determined by the speed and power settings of the laser. The Two Trees Engraving machine TTS-55 is a 5-watt laser, and cutting through materials, especially thick wood, requires several slow passes at 100%. Two Trees has designed this laser with “compression spot technology” which concentrates the beam to squeeze as much power as possible. I found that it burned a bit more aggressively than the Creality CR Laser Falcon, another 5-watt laser we’ve reviewed.

LightBurn includes a Materials Test, located in the main menu under Laser Tools. Ideally, you would test each material you want to engrave or cut, then save that test piece for future reference. I ran the test on a sheet of balsa and easily burned through it.

I wanted to see how the Two Trees TTS-55 handled leather, so I burned my initials into a scrap of suede. It took 15 minutes and 57 seconds, with the design set at 800 mms and the cut line at 500 mms for a single pass. Fun fact: though the image isn’t that dark, the laser did burn all the way through the leather, leaving a reverse image on the flip side and a faint mark on my concrete slab.

When I switched to bamboo, I made another power scale on an old IKEA cutting board. Using the same settings that I used on pine turned the board to cinder in many places, and created smoldering embers in the darkest squares. This is a good time to remind everyone to never let a laser run unattended.

I picked up a fresh IKEA bamboo cutting board and used LightBurn to scale a piece of kitchen clip art to fit it. It burned beautifully without going too deep. This was etched with a single pass at 2000 mms at 50% and took 1 hour and 14 minutes.

Two Trees included a wooden phone holder to practice on, so I etched my blog logo into it. Trying to center the pattern was the hardest part, since these simple lasers do not have any type of layout aid for the material being lasered. The pattern burned smooth and dark with a single pass of 3000 mms at 100%, taking about 7 minutes.

This butterfly is actually an earring pattern that I enlarged to fit a 1/16 inch (2mm) thick, 3-inch disk of craft wood I picked up at Walmart. The Two Trees TTS-55 cut through it easily in one pass at 250 speed 100%, taking 4 minutes and 38 seconds.

I made a pet rock by lasering this skipping stone we picked up during a creek walk. I made the face using the shape tools in LightBurn and etched it into the rock with a 1000 mms single pass at 100%, taking about 3 minutes. The pattern is white because this is blasting away a thin layer of stone rather than burning it.

Finally, I needed to see how photos work when engraved on the Two Trees TTS-55. Laser engraving photos is truly more art than science, and I believe you need the perfect combo of photo, settings and material to really make it work. I used a photo of my kids embellished with clip art from Canva. The image was set at 3000 mms and 90% power, with the clip art at 1000 mms and 90% power. It was trimmed from a larger piece of 3mm light plywood with 3 passes of 250 mms at 100%. The whole thing took 25 minutes and 15 seconds.

Best laser engraver for small business

The Two Trees TTS-55 may be the best laser engraver for small business, but it’s missing features that are commonly found on similar machines and it has to be tethered to a PC to operate. It’s not exactly “plug and play” since you will need to acquire a fireproof base to place it on. You also need a laptop or strong Wi-Fi connection with a phone app to feed files to the machine.

It can engrave an assortment of material, such as wood, cardstock, leather, acrylic, aluminum or painted tiles. The laser is well tuned and can cut through wood up to 8 mm thick, allowing you to create delicate ornaments or sturdy craft projects.

If you are looking for DIY Laser Cutter Machines for business/education/DIY, Please Click Here.

Something isn’t Clear?

Feel free to contact us to inquire how to become the dealer or distributor, and we will be more than happy to answer all of your questions within 24-48 hours.