As air assist is more and more available to users, it has become one essential tool for the laser cutter and engraver machines, especially for laser cutting purposes. Many users have found the amazing benefits and started to realize the importance of such an accessory for laser cutting and engraving. However, some other users might still hold doubts and suspicions about the air assistance system. If you are also looking for answers, you might find some helpful information in this post to make the right conclusion and decision.

What Is An Air Assist?

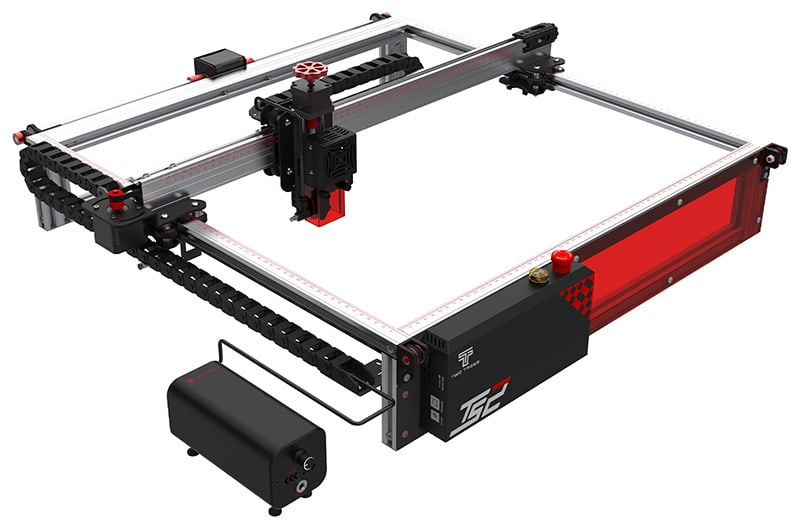

Air assist is the act of blowing high-pressure air onto the material the laser is working on. An air assistance system could either be an external accessory kit or integrated parts of a laser cutter or engraver machine. It usually consists of three major parts: air pump, air tube and air nozzle. The air pump is where the high-pressure air is generated and the pressure is adjusted as per request. The air tube allows the air to flow smoothly to the air nozzle. The air nozzle is like the nozzle of a 3D printer which allows the high-pressure air to work only in the intended position and location.

What Does Air Assist do For Laser Cutter & Engraver?

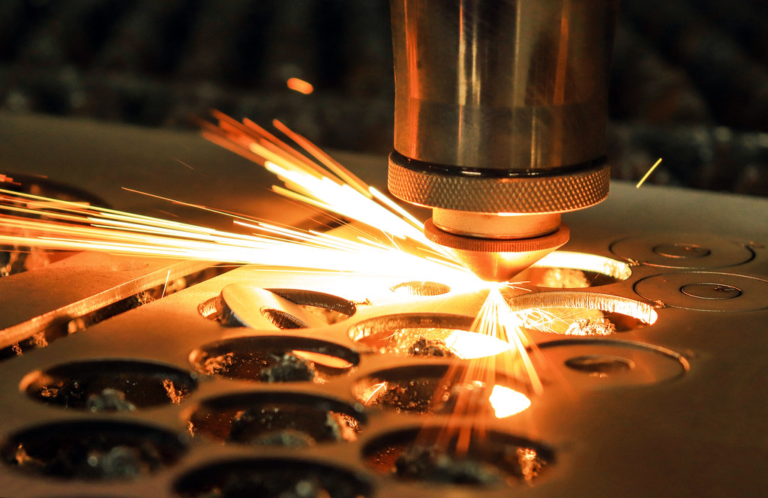

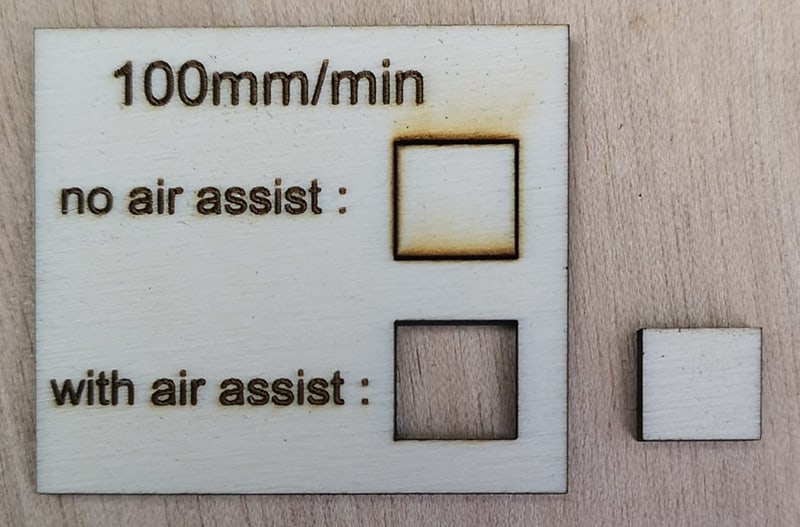

What does an air assist do for a laser machine? If you are a regular user of a laser cutter or laser engraver, you might find it quite normal to see ugly black color remains on your workpieces. Laser engraving and cutting basically use highly-focus laser light to burn through or melt the surface of engraved materials to achieve cutting and engraving purposes. One of the most important works of an air assist is to reduce material combustion and melting via blowing high-pressure air on the working area of the material. It also minimizes heat around the laser head and only dissipates heat where the laser contacts the material. Therefore, it removes debris from around the contact point, prevents the material from burning, and achieves better engraving or laser cutting results.

Apart from this, the air would also blow away dust, smoke, and particles generated from the operation. Without an air assist, these combustion products would possibly pollute your laser lens and weaken the laser light. Though it’s highly recommended to clean the laser lens regularly, the air assistance system would definitely save you lots of trouble.

What are The Benefits?

Though most current consumer laser cutters and engravers do not include an air assist, it’s definitely a cost-effective investment to make. Here are some of the benefits you could enjoy from an air assist system:

- Improve performance: with an air assist, you might see visible improvements on cutting edges and you no longer need to worry about the waste of materials.

- Increase speed: An air assist not only delivers clearer and better edges but also increases the working speed and saves your time.

- More safety: Its high-pressure air would effectively blow away combustible by-products and waste heat to reduce the risk of fire caused by the debris.

How Does It Work?

The research and development of laser cutting and engraving started as early as 1998. It was found that when assisting gas injected at the laser head, the CO2 laser engraver would work more effectively. The injection of assisting gas would initiate an exothermic reaction which is a chemical reaction that releases energy through light or heat. Though with assisting gas, you can get the work done faster, cleaner and smoother, the choice and application of different assisting gas haven’t been the same all the time.

For years, oxygen was the most commonly used gas with air assist for laser engraving. It was later succeeded by nitrogen, which was found to produce a cooler engraving with cleaner edges. This was a perfect option for industries where aesthetics and edge quality were vital. However, it has been discovered that pressurized air is a more economical option with equivalent efficiency to nitrogen and oxygen. That’s why most consumer air assist uses an air pump to generate pressurized air for laser cutting and engraving.

How to Choose an Air Assistance System for Your Laser Machine?

Different manufacturers might have different choices and settings for the air assistance system. Some prefer to produce a separated system to sell as an optional product kit and some prefer to build the air nozzle on the laser machine to have a better setup and design. However, there are a few factors that could be on your top list to consider while choosing an air assist for your laser machine.

- Basic specifications: Among the basic specifications, pressure, nozzle size, and output of an air assist would be some of the most vital values to check. It determines how effective would the high-pressure air is and the overall performance of the air assist system.

- Pressure adjustment options: A fixed air pressure won’t work for all purposes and conditions, thus it’s important to provide an option for users to choose the right pressure when dealing with different materials and in different working environments. Our solution for this is a rotary switch for simple and easy operation.

- Easy to use: No one would like a tool that is difficult to use or operate. Our air assist kit includes all parts and tools to set it up on a laser machine.

- Compatibility: Before you dig more information about an air assist, the first job to do is to check if the system is compatible with your current laser machine or not. Our new air pump and nozzle work for machines including Two Trees Totems/TTS series products and machines from many other brands.

- Durability: A durable device means more stable performance, a lasting life span, and less maintenance work.

- Cost: When talking about cost, it usually refers to the cost-effective ratio. If the value and performance are worth the money, no one would turn to a second choice. The price for a consumer air assistance system including an air pump and all accessories would vary from $69 to $179 from different suppliers and you may choose a quality one within this price range.