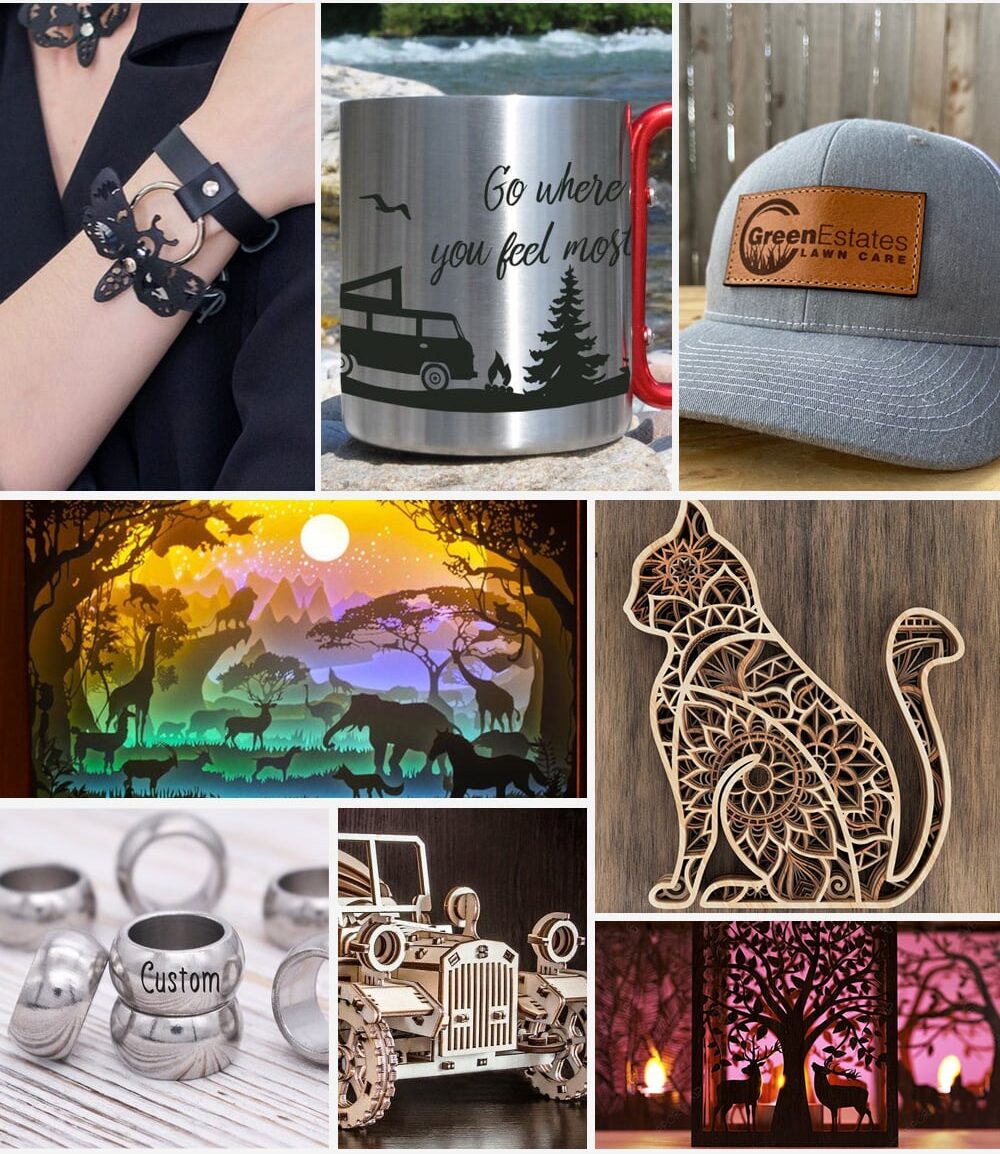

If you are considering starting a small business at home or garage, a compact diode laser engraver & cutter machine would be an ideal tool to start earning money. The ever-growing demand for laser engraving means great market potential and business opportunities. Whether you are planning on wood crafts, theme toy boxes, business card, photoengraving, wall decoration, metal engraving, or customized gifts, you gonna need a quality engraving & cutting machine with delicate details to achieve the best creation performance and results. If you haven’t decided which laser engraver to be your first equipment to start, you are in the right place as we gonna introduce you to the best laser engraver & cutter machine for small businesses – TTS-55.

When comes to choosing the right engraving & cutting machine for your business, there are many factors to consider but laser power, supported materials, costs would always remain on the top of the list. And TTS-55 could be considered the best laser engraver & cutter machine for small businesses in these terms. It is an updated model based on our TT-5.5S desktop laser engraver machine with some major improvements to enhance performance and users’ experience for DIY and creation. Here are some reasons why should every small business starter should consider TTS-55 as the first machine for his engraving business.

Its unique and advanced LD+FAC technology (check this post for more details on the technology) set it apart from any other laser engravers in the market. The compressed laser spot is with higher power density, thinner and clearer trails. The highly focused laser spot allows it cut through 8mm plywood and other material easily.

Whether you are selling leather bags with customized engraved patterns, laser engraved wall clocks, laser cut business cards, cardboard puzzle boxes or laser etched glassware, you won’t need a second machine to get all job done. More materials that could be engraved or cut would include MDF, acrylic, bamboo, anodized aluminum, stainless steel, plastic, paper, rubber, sponge paper, etc.

Instead of digging a hole in your wallet, TTS-55 is with a competitive and alluring price so that every small business owner and DIY creator could have the chance to taste the first bite of technology. You might find more information on this laser engraver & cutter machine in our official store.

The laser engraving machine is 570 * 510 * 150mm in size and less than 5kg in weight. Its lightweight and compact design are perfect for home business and DIY enthusiasts as users won’t need extra space to set up the device. With proper ventilation, you can place it right in the study room, garage, or workshop.

The 60% pre-assembled parts with modular design enable beginner users to complete installation within half-hour under the guidance of the user manual. Once imported configuration & settings file (Click to download all files here.) which are included in the TF card delivered together, the machine is ready to go. What’s more, TTS-55 is designed with a mobile APP to connect with the laser engraver via Wifi. Users could engrave their daily selfies or photos right from their mobile phones, control and monitor the whole process while being absent.

6th: Safer Design

When comes to laser engraving or cutting business, safety is always one of the top concerns. In terms of safety, we add an extra emergency stop switch so users could shut down the machine with a single push at any time. The upgraded 32bit control board also allows users to add flame detectors to take safety to next level. It is also recommended to have a metal pad and working table like this one sit beneath the machine.

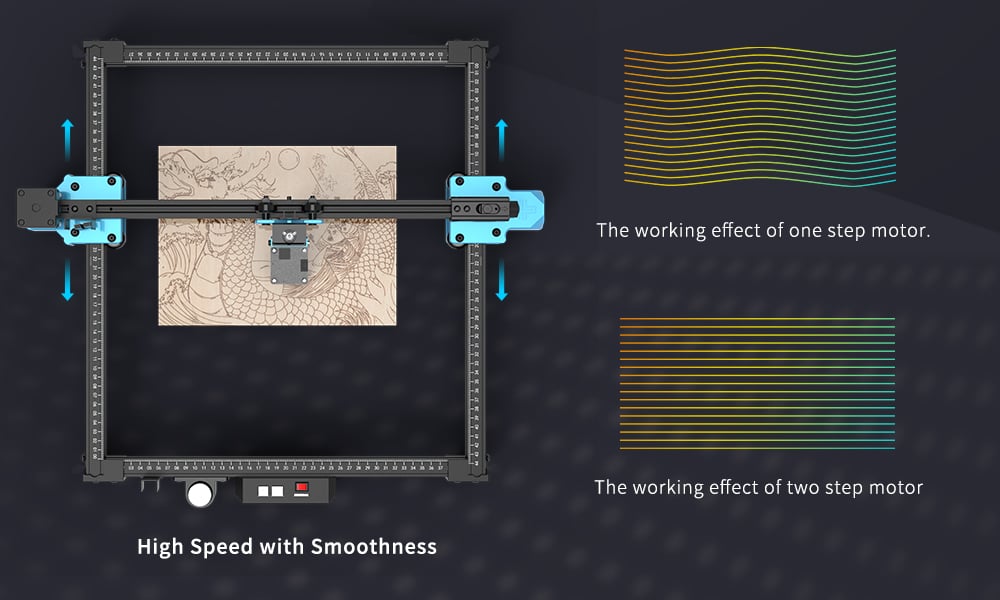

Another feature that set TTS-55 apart from other laser engravers in the market is its dual y-axis stepper motor design. Instead of using a single motor for Y-axis movement, TTS-55 utilizes one motor on both sides of the Y-axis. Once engraving or cutting begins, the control board would commend both motors to move in the same direction and at the same speed. The synchronous movement ensures a higher speed and less wobbling which leads to higher precision and faster engraving speed.

To more customization possibilities for DIY users, we have upgraded the previous motherboard to ESP32. The upgraded motherboard not only enables users to connect the engraver with the mobile APP via Wifi but also enables users to add extra functions and features to the machine including a flame detector, external end-stop switch, vibration sensor & switch, and control screen. Apart from that the upgrade also means faster reading, quick response, and more storage for customized code lines. If you are a creator and enjoy playing around with codes, this machine is definitely worth trying.

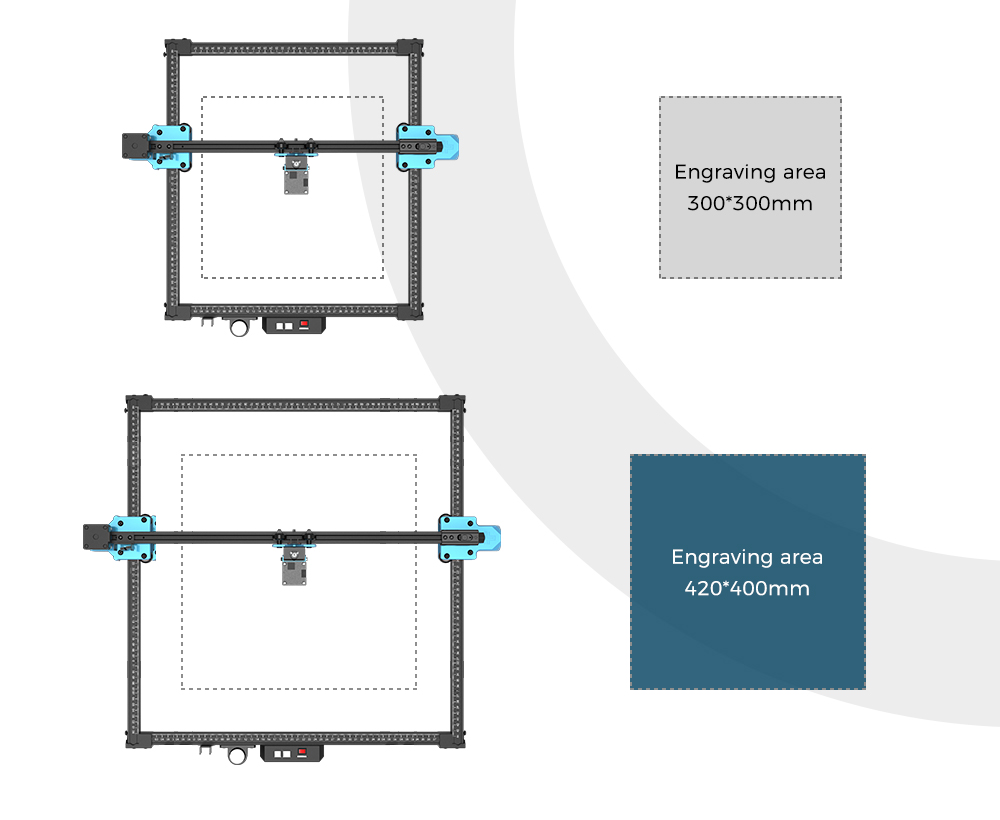

The original laser engraver machine is with 300*300mm engraving size which would meet demands for most DIY projects and your business. However, for projects with large objects involved, it would be inefficient thus we provide extra extension kits as optional accessories to increase the engraving size to 420*400mm. If you work regularly on projects with higher demands for engraving size, TTS-55 and the extension kit would be worth your time for research.

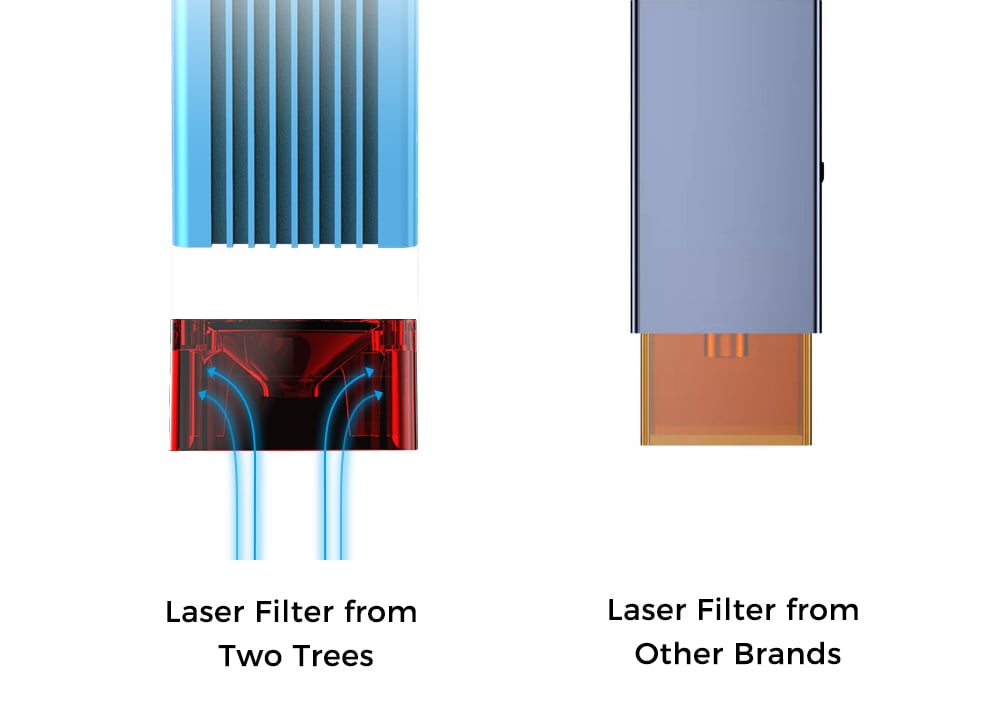

Laser engravers and cutters utilize high-density laser light which might cause permanent damage to the eyes if without proper eye protection. Thus most desktop laser engraver machines are packed with the protective goggle. And another protection is to attach a laser filter cover beneath the laser module to filter harmful light against your eyes. However, another problem was raised as the smoke might be contained within the laser filter which would then stain your laser, block laser light, weaken the laser power and affect engraving and cutting performance.

To avoid the problem and provide more efficient smoke exhaustion, we have updated the laser filter cover with a unique funnel design. The funnel design, instead of forcing smoke to spread upward to stain laser, makes generated smoke flow to all sides and then out of the filter cover from the opening.

As mentioned a large amount of smoke would be generated during the engraving process which would then block laser light and affect performance, thus an air assistance kit would be used to blow away the smoke to get ideal performance and result. To provide with better users experience and delivery better engraves and cuts, we preserve extra space on the laser module to enable users to set up an air assistant kit with our unique bracket and mounting system. Though the bracket and air assistant kit are still under development, users could expect it to come into the market very soon.

1ST: Multiple scales on profile: The profile of TTS-55 is designed with a ruler scale which enables users to quickly make measurements on objects to surface to engrave or cut.

2nd: Emergency stop button: The emergency switch allows users to shut down the machine immediately with a single push.

3rd: Stepped laser focusing column: The focusing column enables users quickly adjust laser focal length for engraving and cutting different depths.

Since the invention of 1st working laser, the laser engraving and cutting market has been growing ever since and has developed into a market with a 2.8 billion US dollars annual turnover and an 8% year-to-year growth rate. Can I make money with laser cutter & engraver? The answer is clearly “yes” and the laser cutting & engraving business is for sure one profitable and promising business for entrepreneurs.

You can either run a local store, online shop, or even build your own brand with engraved and cut products with laser engraver & cutter machines. We have organized the top 13 laser engraving and cutting business ideas in our previous posts. You might check the full list and share it if you find it helpful.

Diode, CO2, and fiber laser cutters are the three most common laser types on the market. The costs for a regular diode laser engrave vary from $100-$15000 due to differences in laser power, product quality and performance. FOR a CO2 laser engraver, the costs would be a bit higher from $1000-$5,000. A fiber laser cutter would be with the highest cost among these three laser types and the price would be as high as $40,000. You might check our post “Which laser cutter & engraver to buy?” to find the pros and cons for each laser type.